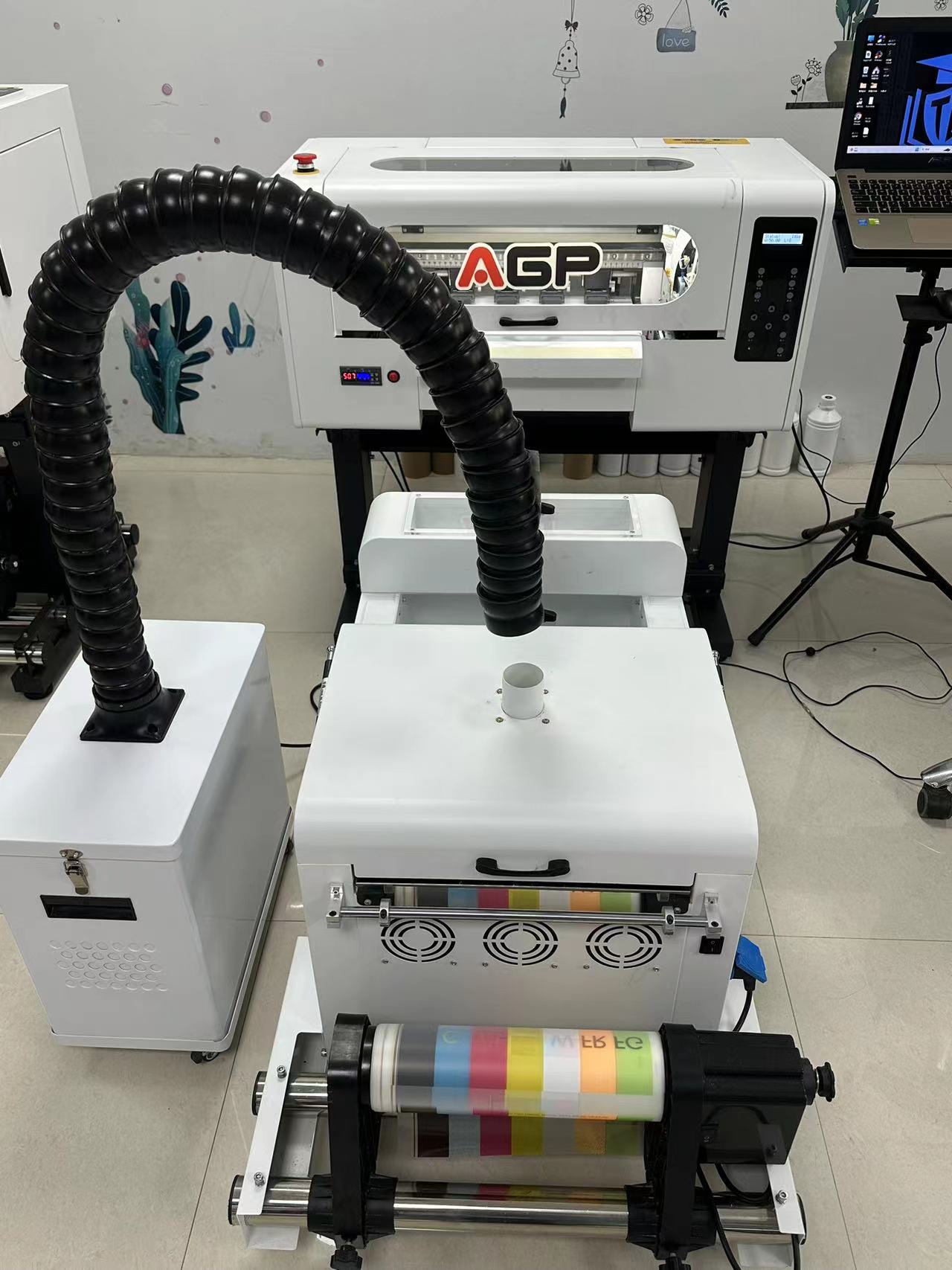

AGP 30cm DTF Printer with Powder Shaker: Meeting Your Unique Customerized Printing Needs

Compared with the DTG direct-to garment printer, this DTF solution is flexible in positioning due to its printing on PET film first, and then heat press on fabrics, which is suitable for mass production of T-shirt Logo Label printing. This A3 DTF printer with new technology—-no need to make plates, no need for pre-treatment, and can be used for any garment printing.

Its excellent flexibility allows it to adapt to a variety of different printing needs. Compared with traditional direct-to-garment printing (DTG), it can print on PET film first, and then transfer the pattern to the fabric through heat pressing. This process allows for more freedom in printing positions, especially suitable for batch T-shirts. Production of logos. In addition, this 30cm DTF Printer adopts new technology, which requires no layout and pre-processing. It can be used for any type of clothing printing, greatly simplifying the printing process and improving work efficiency.

Printing Process

What is DTF printing?

- DTF (Direct-to-Film) printing is a method where designs are printed onto a special PET film and then transferred onto the fabric using a heat press. This technique offers flexibility in positioning designs on garments and eliminates the need for pre-treatment.

How does DTF printing compare to DTG printing?

- DTF printing differs from DTG printing in that it prints onto a film first, which is then transferred onto fabric. This allows for more precise design placement and is particularly suitable for mass production of garment labels.

What are the advantages of DTF printing?

- DTF printing offers advantages such as flexibility in design placement, suitability for mass production, elimination of pre-treatment processes, and compatibility with various types of fabrics. It also streamlines the printing workflow and reduces production time.

What maintenance is required for DTF printers?

- Regular maintenance of DTF printers includes cleaning printheads, replacing consumables such as ink and film, and ensuring proper calibration for accurate printing.