AGP UV DTF: A Comprehensive Guide to Direct-to-Film Technology

UV DTF (Direct to Film) printing is a cutting-edge technology that enables direct printing of designs onto a special film using UV-curable ink. This ink is cured by UV light, creating vibrant and durable prints that can be transferred onto various surfaces. UV DTF printing offers high-quality results, versatility, and cost-effectiveness for businesses and individuals alike.

UV DTF (Direct to Film) printing is a modern printing method that allows for direct printing of designs onto a special film using UV-curable ink. This ink is cured by UV light, resulting in vibrant and durable prints that can be transferred onto a variety of surfaces. UV DTF printing is known for its high-quality results, versatility, and cost-effectiveness, making it a popular choice for businesses and individuals looking to create custom designs on different materials. Let’s take a look at the questions and answers about UV DTF now.

Q1: How does a UV DTF Printer work?

A1: A UV DTF Printer uses UV-curable ink, which is a type of ink that hardens when exposed to ultraviolet (UV) light. The printer applies the ink onto a special film, and then a UV light source cures the ink, making it adhere to the film. The printed design can then be transferred onto a surface using a heat press.

Q2: What are some common applications of UV DTF Printing?

A2: Some common applications of UV DTF Printing include:

- Printing designs onto textiles, such as t-shirts, hats, and bags.

- Printing designs onto ceramics, such as mugs, plates, and tiles.

- Printing designs onto glass, such as windows, mirrors, and glassware.

- Printing designs onto wood, metal, and plastic surfaces.

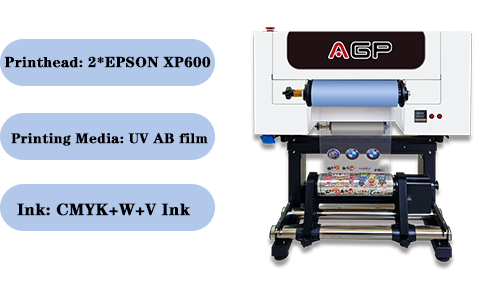

Q3: What are the key components of a UV DTF Printer?

A3: The key components of a UV DTF Printer include the printer itself, UV-curable ink, a UV light source, a heat press, and special films designed for UV DTF printing.

Q4: How does UV DTF Printing compare to other printing methods, like screen printing or sublimation printing?

A4: UV DTF Printing offers advantages over other methods, such as the ability to print on a wider range of surfaces, including irregularly shaped objects, and the ability to print on both light and dark-colored surfaces.

Q5: What are some common maintenance tasks for UV DTF Printers?

A5: Common maintenance tasks for UV DTF Printers include cleaning the printer’s print heads, checking and replacing ink cartridges, and calibrating the printer for optimal print quality.