AGP Wholesale UV DTF 60cm Width Printer UV Sticker Printer UV AB Film Crystal Label Printer UV Stickers Suitable for Acrylic Leather Plastic

UV DTF printing, short for UV Direct-to-Film printing, is an innovative crystal label printing process that uses UV-cured inks to print images or designs directly onto film or other rigid materials. This technology entails adhesives, white UV DTF ink, UV varnish, etc. A release UV DTF film can be used to print different patterns that you design with your inspiration, which are then laid onto a transfer film and transferred. UV DTF printed stickers can be suitable for many hard surfaces and can be removed and reused without additional processing.UV DTF prints are resistant to water, alkalis, wear, and tear, corrosion, sunlight, and oxidation. This makes them ideal for a wide range of applications. UV DTF printers serve various industries, from household items to electronics and gifts.

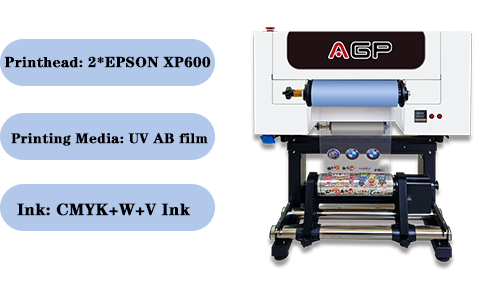

UV DTF Printer parameter

| Model | UV-S604 | ||

| Printhead | Epson I3200-U1/Epson I1600-U1 | ||

| Quantity | 3 | 4 | |

| Printing Color | W+CMYK+V | G+W+CMYK+V | |

| Printing Speed | I3200-U1 | 6PASS 3-10m²/h 8PASS 2.5-8m²/h 12PASS2-6m²/h | |

| 11600-U1 | 4PASS 4m²/h 6PASS 3m²/h 8PASS 2m²/h | ||

| Printing Size | 600mm | ||

| RIP Software | Riin/Flexiprint/Cadlink/Maintop | ||

| Print Media | UV AB Film | ||

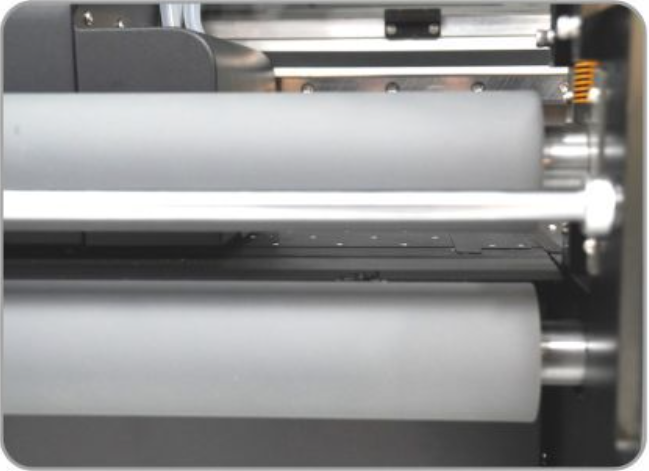

| Laminator | Integrated automatic laminator | ||

| Ink supply system | White ink circulation and stirring | ||

| Ink curing | Water cooler+UVLED lamp (to ensure long-term high-intensity operation) | ||

| Power Supply | 110V/220V 50-60HZ | ||

|

Sleeping:45W Standby:1100W Working:2000W |

|||

| Work Environment | Temperature:20°C-30°C humidity:35%-65% | ||

| Dimension | 1800*870*1600mm | ||

UV DTF Printer Features

White color and varnish synchronous printing Printing and laminating at the same time

What UV DTF printing is

UV DTF printing, short for UV Direct-to-Film printing, is an innovative crystal label printing process that uses UV-cured inks to print images or designs directly onto film or other rigid materials.

This technology entails adhesives, white UV DTF ink, UV varnish, etc. A release UV DTF film can be used to print different patterns that you design with your inspiration, which are then laid onto a transfer film and transferred. UV DTF printed stickers can be suitable for many hard surfaces and can be removed and reused without additional processing.

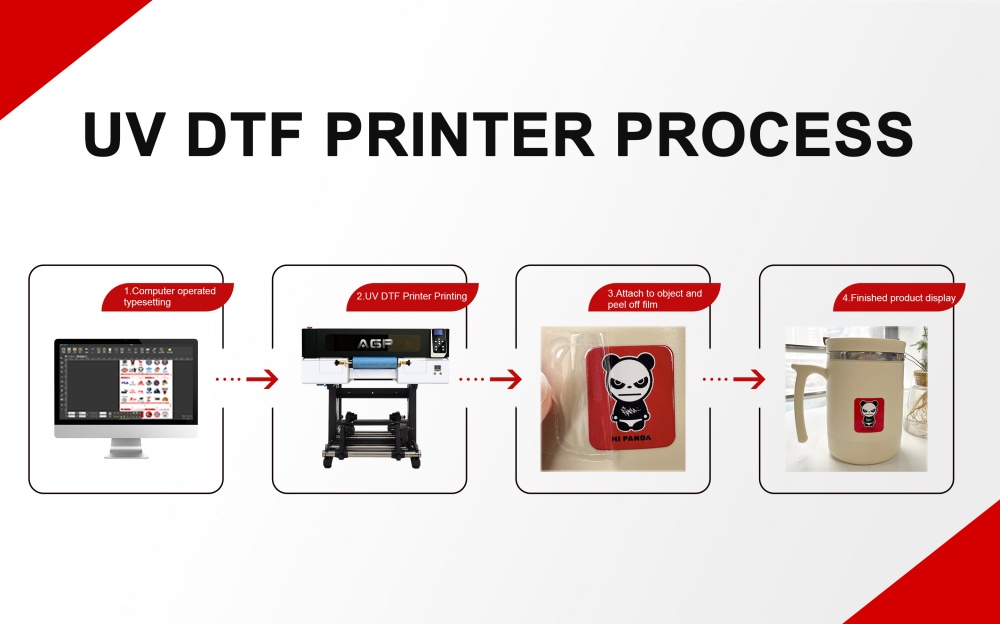

How UV DTF printers work

Option 1: Print directly on the product

Option 2: Use UV DTF film transfer, also known as AB film

First, printing ink will be solidified quickly when exposed to UV light from an LED and then the images are printed on the “A” film.

At the same time, there is a kind of film together functioning as production with film “A”.

After printing, film A is adhered to the film B by a laminator. Film A is on the back side of the image and Film B is on the front side.

Then comes the step to transfer the design. We can cut out the outline of the image with scissors or a cutter (for mass production).

Removing film A and posting film B on the object. The design will firmly adhere to the object.

The whole process does not require heat pressure, just finger pressure, and after a few seconds, the film can be peeled off and the design is successfully transferred to the print media.

UV DTF Advantages:

Durability and versatility:

UV DTF prints resist water, alkalis, wear, and tear, corrosion, sunlight, and oxidation.

This makes them ideal for a wide range of applications.

Low minimum order quantities:

Suitable for short-run production, requiring no plate making and can be applied to curved surfaces, cylinders, and flat surfaces, reducing the cost of customization.

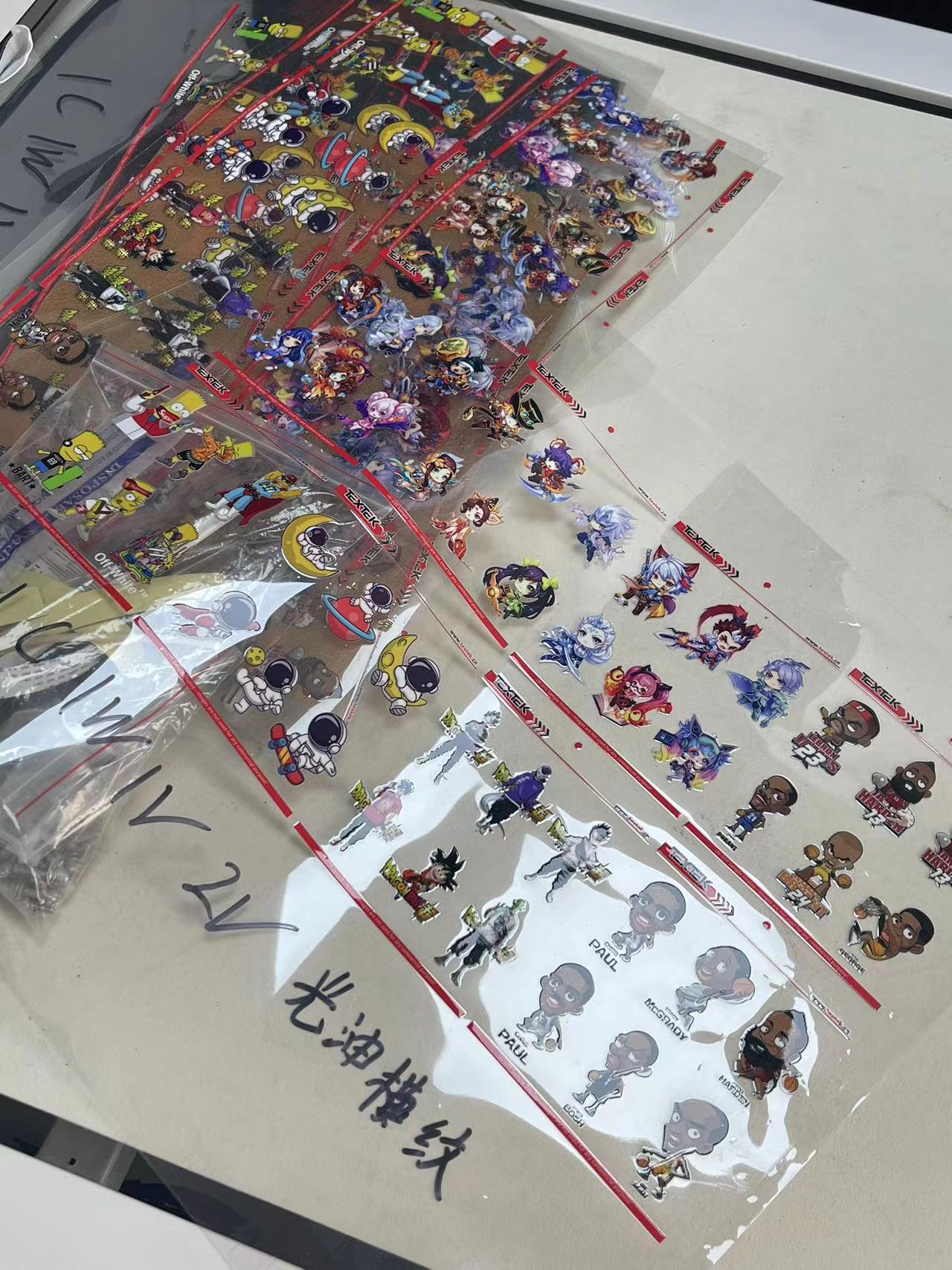

Wide range of applications:

UV DTF printers serve various industries, from household items to electronics and gifts.

Efficiency:

Compared to UV flatbed printers, UV DTF printers are more efficient, especially when using roll materials.