Cold peel film or Hot peel film? Which film you should choose?

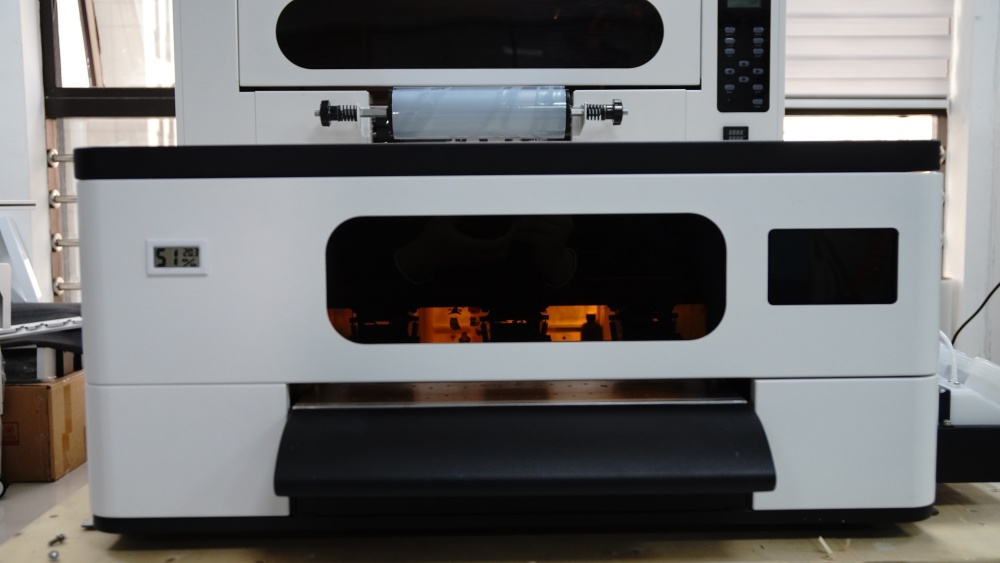

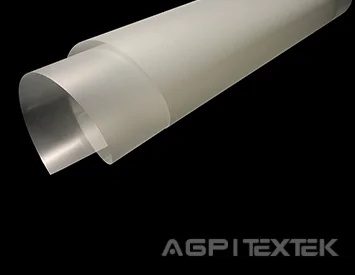

DTF printing requires DTF film, which we usually call PET film, but not all PET films can be used for DTF printing. Compared to regular PET films, DTF films have a special ink-absorbing coating. As a result, the film usually looks matte and frosted, rather than transparent. Untreated, low-quality films may be cheaper, but they may stain, not stick or damage your clothing.

DTF Printing has a wide range of uses, the technology and effects are constantly being updated. What remains unchanged is that when the DTF film is hot transferred on the substrate, the film needs to be peeled off to complete the entire hot transferring process.

However, some DTF PET films need to be hot-peeled, while others need to be cold-peeled. Many customers will ask why this is? Which film is better?

Today, we will take you to learn more about the DTF film.

1.Hot Peel Film

The main release component of hot peel film is wax, the ink absorption performance is relatively poor, and small letters are easy to fall off, but the surface becomes brighter after it is completely cooled.It can save waiting time, after transferring the pattern to the fabric through the press machine, peel it off while it is still hot.

If it is not peeled off in time within 9 seconds (ambient temperature 35°C), or when the film surface temperature is higher than 100°C, the gule will cold stick to the clothes, causing difficulties in peeling off , and there may be problems such as pattern residue.

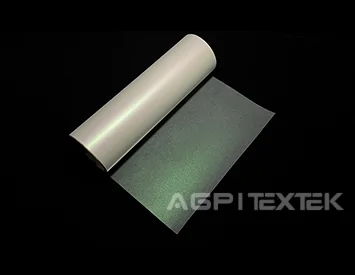

2.Cold Peel Film

The main release component of cold peel film is silicon, the product has good stability, and the color becomes matte after cooling down.

For this type film it need wait for the DTF film to cool down and then gently peel off(suggest temperature below 55 ℃).otherwise, it will cause difficulties in peeling off to damage the pattern.

Four basic factors for choosing DTF printing film

1.The pattern after transfer has a texture like PU glue, with strong stretch resilience and no deformation. It feels softer than glue (30~50% softer than the pattern printed with oil-based film)

2.It is suitable for most inks on the market. It can print 100% of the ink volume without any ink accumulation or bleeding.

3.The surface of the film is dry and can be sprinkled with 50-200 powder without sticking. The picture is a picture and the powder is powder. Where there is ink, the powder will stick. Where there is no ink, it will be spotless.

4.The release is easy and clean, leaving no ink on the printing film and no layers on the pattern.

AGP provides a full range of DTF films including cold peel, hot peel, cold and hot peel, etc., with leading research and development formulas, good release and stability. Just choose the most suitable one based on your demands!