Daily maintenance of UV DTF printer

As we all know, in addition to regular maintenance, daily maintenance of UV DTF printers is also essential. The printing status of the machine will directly affect the quality of the printed product. And if the daily maintenance work is done well, the service life of the machine will be extended, which will save a lot of maintenance costs.

1. Daily maintenance of the printhead

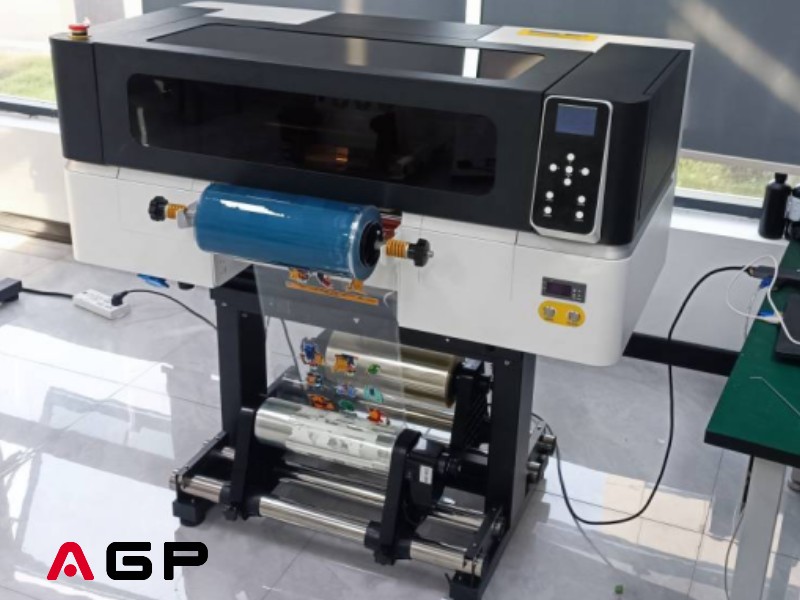

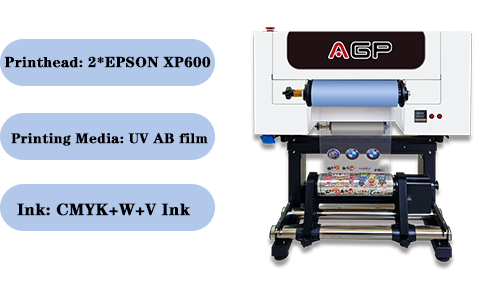

The printhead is one of the most important parts in a UV DTF printer, so it is the part that needs the most careful treatment. It is also the focus of daily maintenance.

(1) After work every day

① Test the printhead, keep the test ink strip after printing, and test it again before work tomorrow for comparison.

② Return the printhead to the top of the ink pad to allow the ink pad to continue to moisturize the printhead. Remember not to leave the printhead exposed to the air, because UV DTF ink is very easy to dry. When the machine is not working, the printhead must be placed above the ink pad, otherwise the ink will dry and easily clog the printhead. At the very least, the printhead needs to be cleaned, and at the worst, the printhead will be scrapped.

(2) Before work every day

① Test the printhead after turning on the machine and compare it with the test strip from the previous day. If the ink is disconnected, the printhead needs to be cleaned until the test strip is complete.

② Test again after cleaning until the ink strip is similar to the previous day.

The print head needs to be tested before and after work to ensure that the print head is in the best condition before printing. Otherwise, the quality of the printed product will be uneven, resulting in the entire product being unusable and wasting a lot of consumables costs.

2. Avoid light

Due to the special nature of UV ink, it dries when exposed to light, so it is very important to avoid light. Whether in the working process or when the machine is resting, the ink tank, ink tube, nozzle, etc. must be kept away from light.

In addition, always pay attention to whether the ink in the ink tank has dried up. If you find that the ink is dry, replace the ink in time and stop using the original ink.

AGP recommends that if your production demand is not particularly large, you can choose a small capacity ink. Once the ink is opened, it will be exposed to light and needs to be used up in a short time. 500ml and 100ml small capacity ink can meet the needs of many small manufacturers.

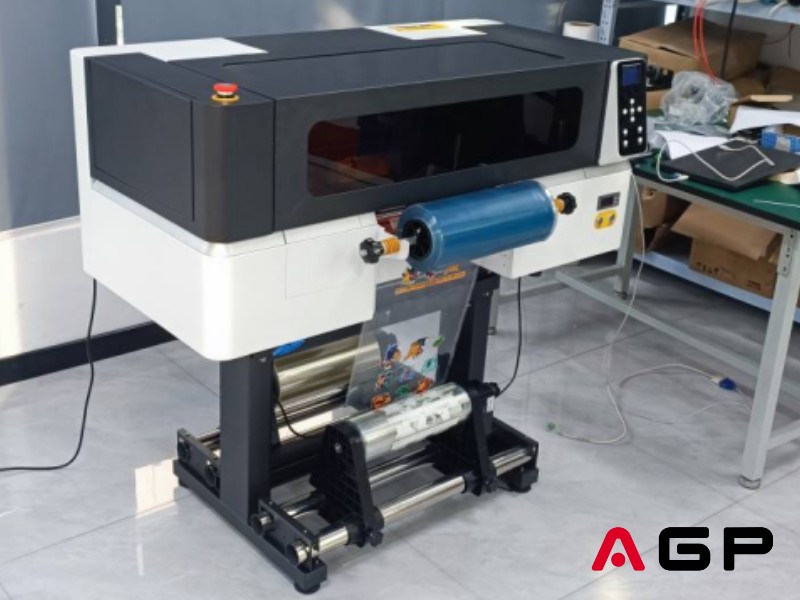

3. Keep the printing film dry and smooth

So if conditions permit, keep the working environment dry. If conditions are limited, observe the state of the printing film before each printing. If it is damp, replace the printing film.

4. Keep the machine clean and tidy

Before daily work, you need to wipe the dust and debris on the surface of the machine, and tidy up the environment around the machine, keep the working environment clean, and then turn on the machine. To prevent dust or other foreign matter from affecting the machine’s work, which may seriously damage the machine’s nozzle.

Daily maintenance of UV DTF printers needs to form a daily habit, so as to ensure the best working effect of the machine, reduce the occurrence of minor printer problems, and greatly reduce the probability of major problems. If a problem is found, it should be dealt with in time.