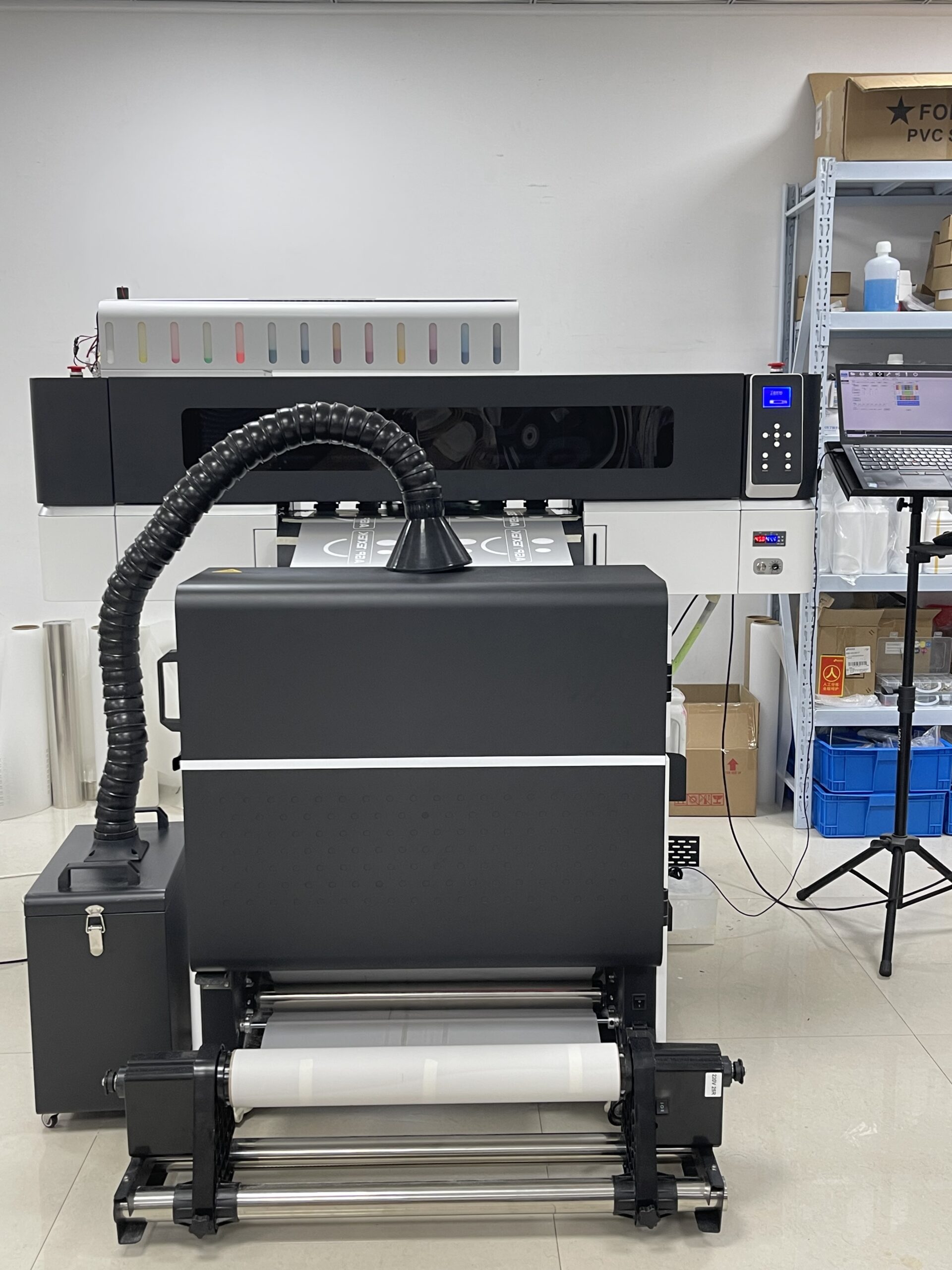

DTF Printing whiteness is not enough? Still transparent? Here is the solution!

In the practice of DTF thermal transfer technology, there may be a troubling problem – impure white, especially when dealing with light backgrounds or pursuing patterns with high color saturation, the DTF finished product will appear transparent.

As the basis and base color of the pattern, the purity of white ink directly determines the visual effect and quality of DTF Printing. So, why does this happen? And how to solve it?

Follow AGP to explore the secrets behind white ink heat transfer.

Why is the whiteness of DTF not enough?

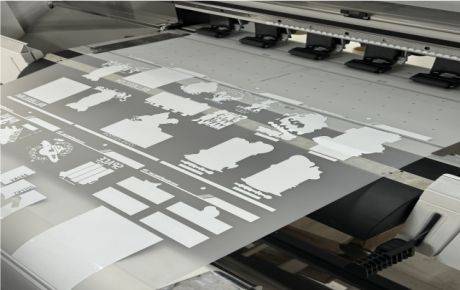

1. The problem of fineness of white ink particles

The thickness of white ink particles directly affects the printing effect. Coarse and unevenly dispersed particles can easily cause the surface of the printed white heat transfer to have a granular feel or tiny black spots, making it appear gray and not pure enough.

2. White ink formula factors

In order to reduce costs, some ink manufacturers may mix other color components into white ink. This impurity in the formula will directly cause the printed white to fail to achieve the expected purity.

3. Incorrect color management settings

The color management settings of the printer are the key to controlling the printing effect. If the parameters are not set properly, even if the white ink is of high quality, it is difficult to present a perfect printing effect.

Targeted solutions

Select high-quality toner

Choosing white toner or liquid white ink with fine particles and high purity is the first step to improve the white effect. This can not only effectively reduce the granularity, but also ensure that the printed white is purer and brighter. Choose some inks with higher saturation and better fluency

Trust regular brands and channels

When purchasing DTF printers and their consumables, regular brands and channels should be given priority. These brands usually have stricter control over product quality and can reduce poor printing results caused by ink quality problems.

Accurately adjust color management settings

According to actual needs, finely adjust the color management settings of the white ink heat transfer printer. This includes but is not limited to the adjustment of parameters such as color mode, brightness, contrast, etc., so that the printed white meets the design requirements and has a high degree of purity.

Regularly maintain the printer

Maintaining the printer in good condition is also an important factor in ensuring print quality. Regularly cleaning parts such as nozzles and ink tanks that are prone to residual ink can also effectively extend the life of the printer.

Conclusion

The problem of impure white in DTF technology often stems from multiple aspects such as white ink particle size, formula selection and color management settings.

This problem can be effectively avoided by selecting high-quality toner, trusting regular brands and channels, accurately adjusting color management settings, and regularly maintaining printers.

If you encounter other confusing problems during the printing process, please feel free to contact us and AGP will wholeheartedly provide you with professional solutions.