Fluorescent Vest Printing with AGP 60cm DTF-T654 Printer: Bright Safety, Enhanced Visibility

A vest is a sleeveless garment typically worn over a shirt or as outerwear. It is commonly used in work environments like warehouses or construction sites for visibility and safety. Safety vests, in particular, are often made of bright, reflective materials to enhance visibility, especially in low-light conditions. These vests can feature multiple pockets, zippers, and seams for functionality, and they are crucial for keeping workers visible and protected on the job.

How to Print Fluorescent Vest Using AGP DTF Printer?

A vest is a sleeveless garment typically worn over a shirt or as outerwear. It is commonly used in work environments like warehouses or construction sites for visibility and safety. Safety vests, in particular, are often made of bright, reflective materials to enhance visibility, especially in low-light conditions. These vests can feature multiple pockets, zippers, and seams for functionality, and they are crucial for keeping workers visible and protected on the job.

How to Print Fluorescent Vest Using AGP DTF Printer?

Project Overview

This case shows how vibrant fluorescent patterns can be transferred onto tank tops using DTF (Direct Transfer) technology. This technology not only provides colorful visual effects, but also adds style and utility to a variety of sportswear, workwear, promotional items, etc. DTF printers perform particularly well in complex fluorescent color applications.

Materials Required

DTF printer (fluorescent color support)

DTF fluorescent ink

DTF transfer film

DTF hot melt powder

Undershirt (optional cotton, polyester or blended material)

Heat press

RIP design software (e.g. FlexiPrint or Maintop)

Steps and processes shown

1. Design the pattern

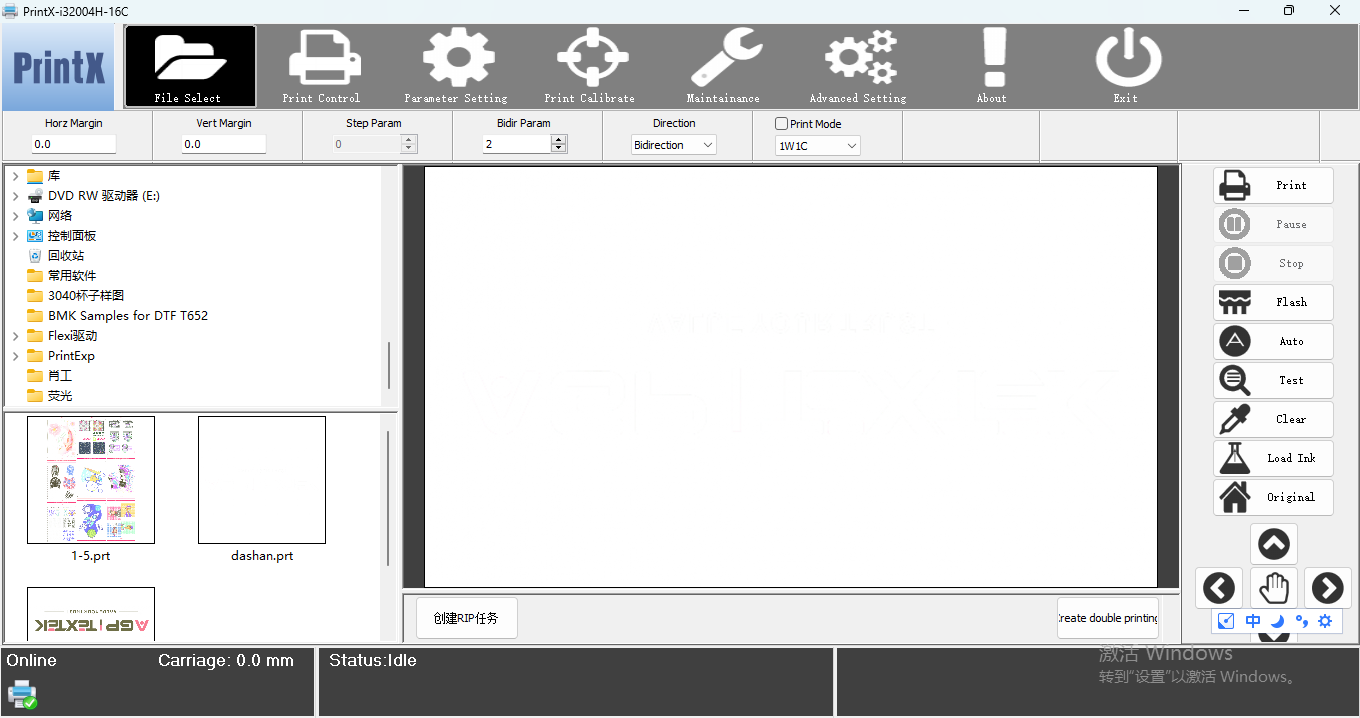

First, we use RIP design software (such as FlexiPrint or Maintop) to create unique fluorescent patterns to ensure that the design takes full advantage of the fluorescent colors.RIP software plays a key role in adjusting the color performance and printing effect, so using genuine software ensures high quality output.

2. Setting up the DTF Printer

Next, prepare the DTF printer by making sure the fluorescent ink is loaded and the DTF transfer film is properly loaded into the printer. Before starting a large-scale print run, it is recommended to make a test print to ensure that the color brightness and pattern details are as expected.

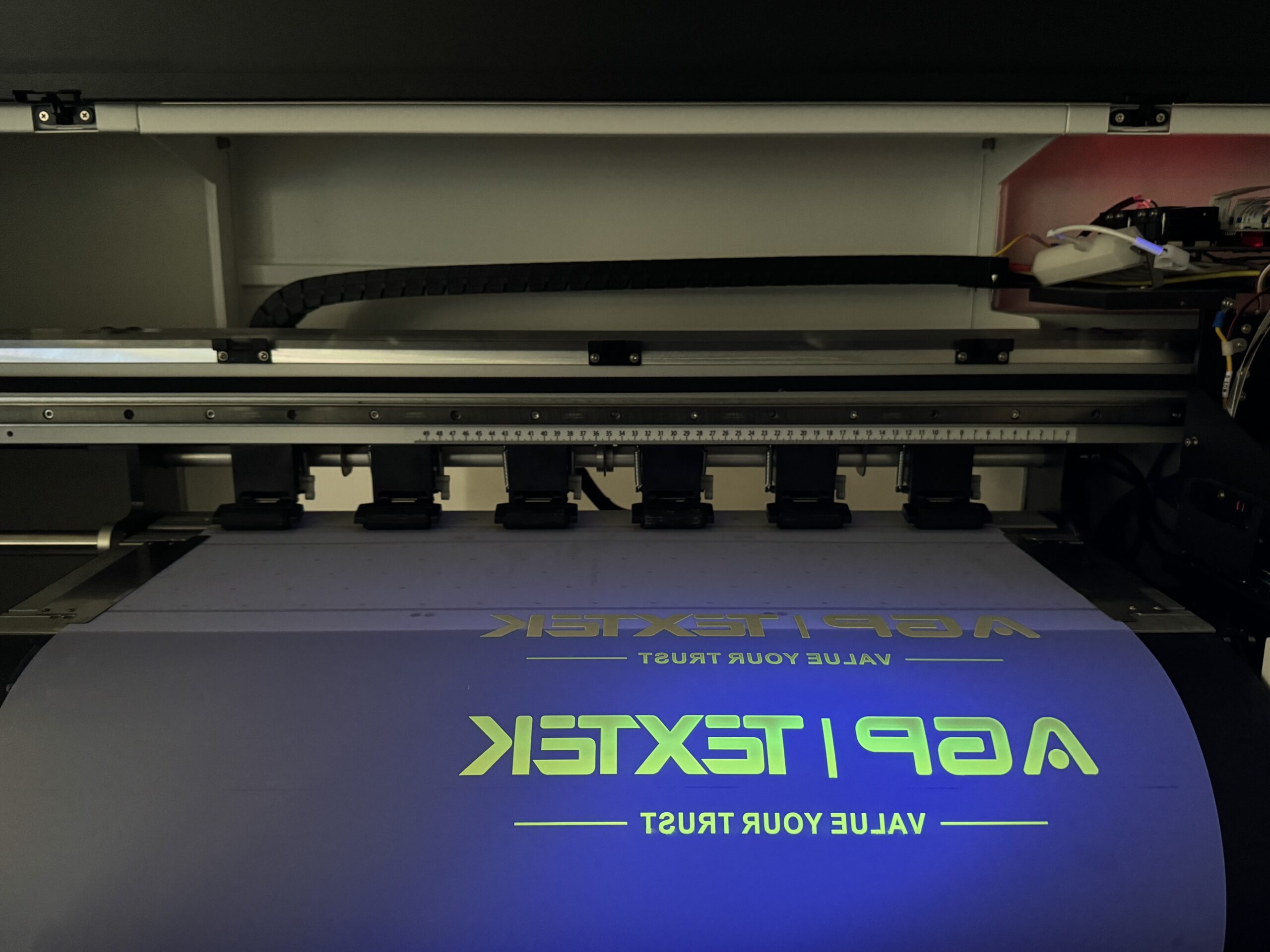

3. Pattern Printing

Upload the design to the DTF printer and start printing. Using DTF fluorescent inks results in brightly printed patterns that produce stunning visual effects even under UV conditions. This ink is particularly suitable for designing eye-catching garments such as undershirts, running suits, training suits or safety uniforms.

4. Applying hot melt powder and curing

After printing, the hot melt powder is evenly sprinkled on the surface of the moist DTF film. For most companies, the use of an automatic powder dispenser for dusting and curing is a more efficient option. For small businesses or home workshops, manual dusting is also feasible. The transfer film is then placed in an oven or a heat press to cure the powder to ensure strong adhesion and crisp pattern detail.

5. Preparing the Vest and Transferring

Prior to the heat press transfer, the undershirt is placed on the heat press table and preheated to ensure that the surface of the fabric is flat and wrinkle free. This step is critical to the final print result and the flat fabric helps to achieve a more accurate transfer.

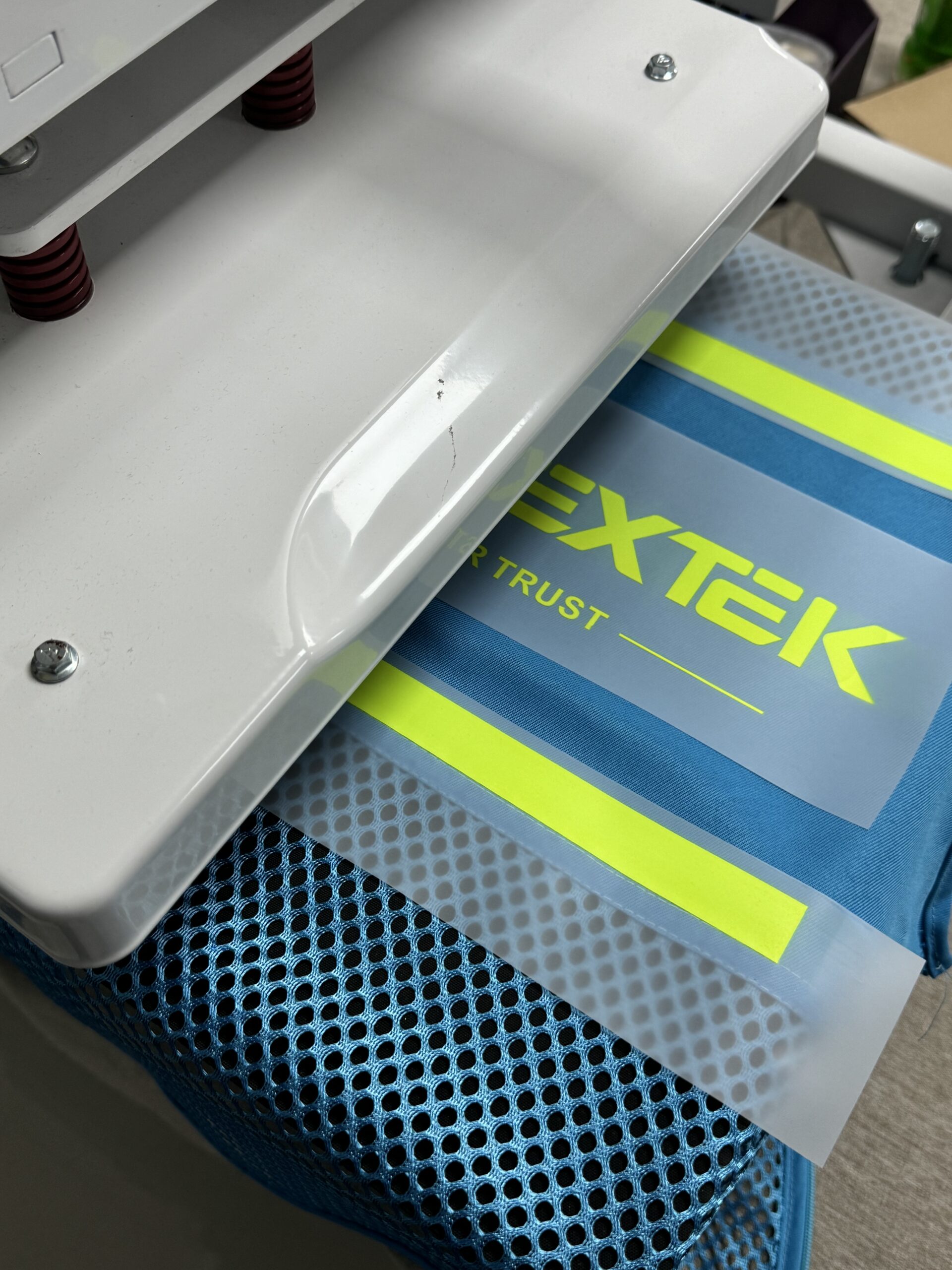

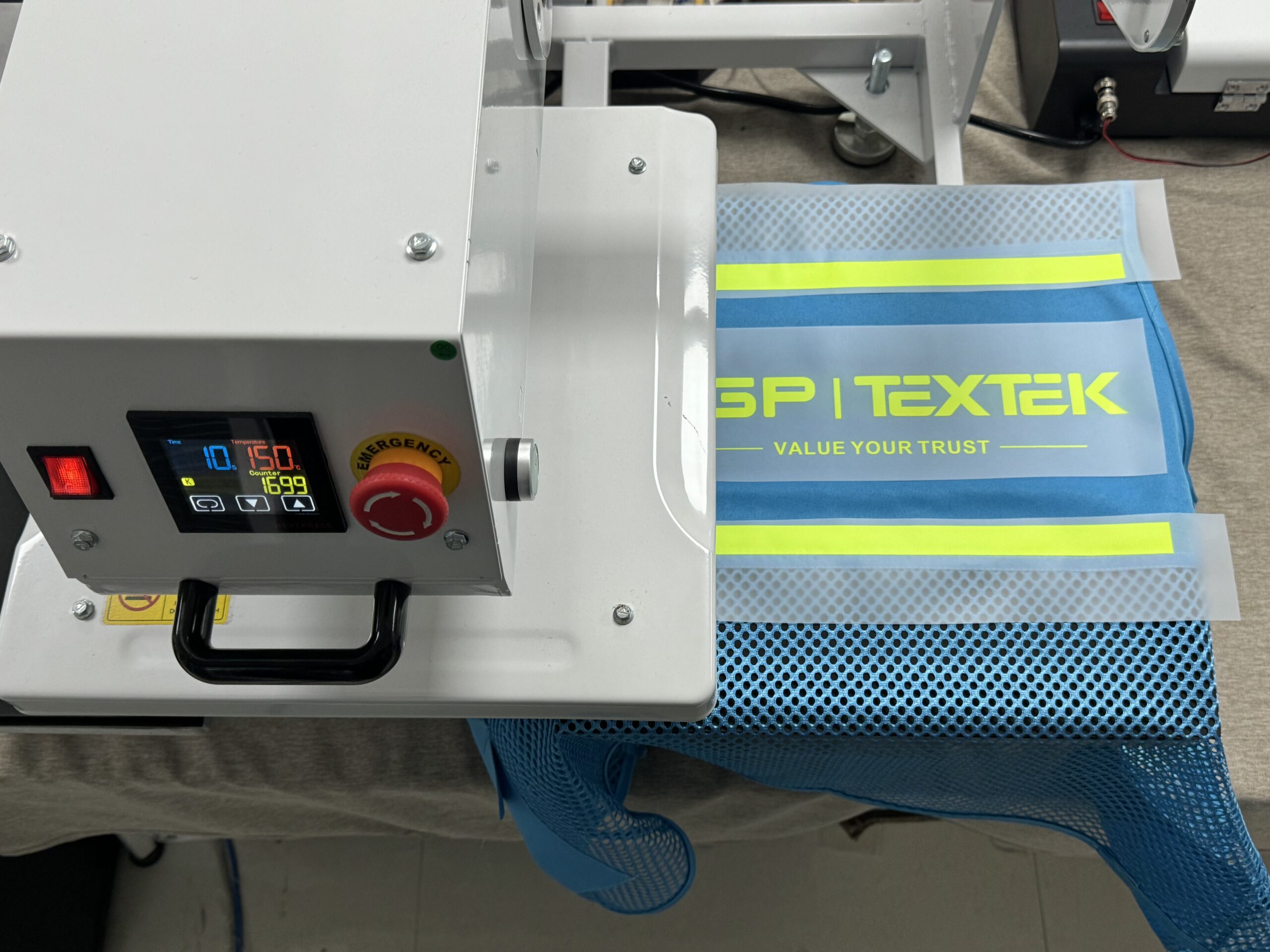

6. Hot Press Transfer

Disconnect the printed transfer film on the surface of the undershirt and transfer using the heat press. Ensure that the temperature and time of the heat press reaches the recommended settings, usually around 160° for 15 to 20 seconds. The heating action of the hot press activates the adhesive on the film, allowing the pattern to adhere firmly to the undershirt.

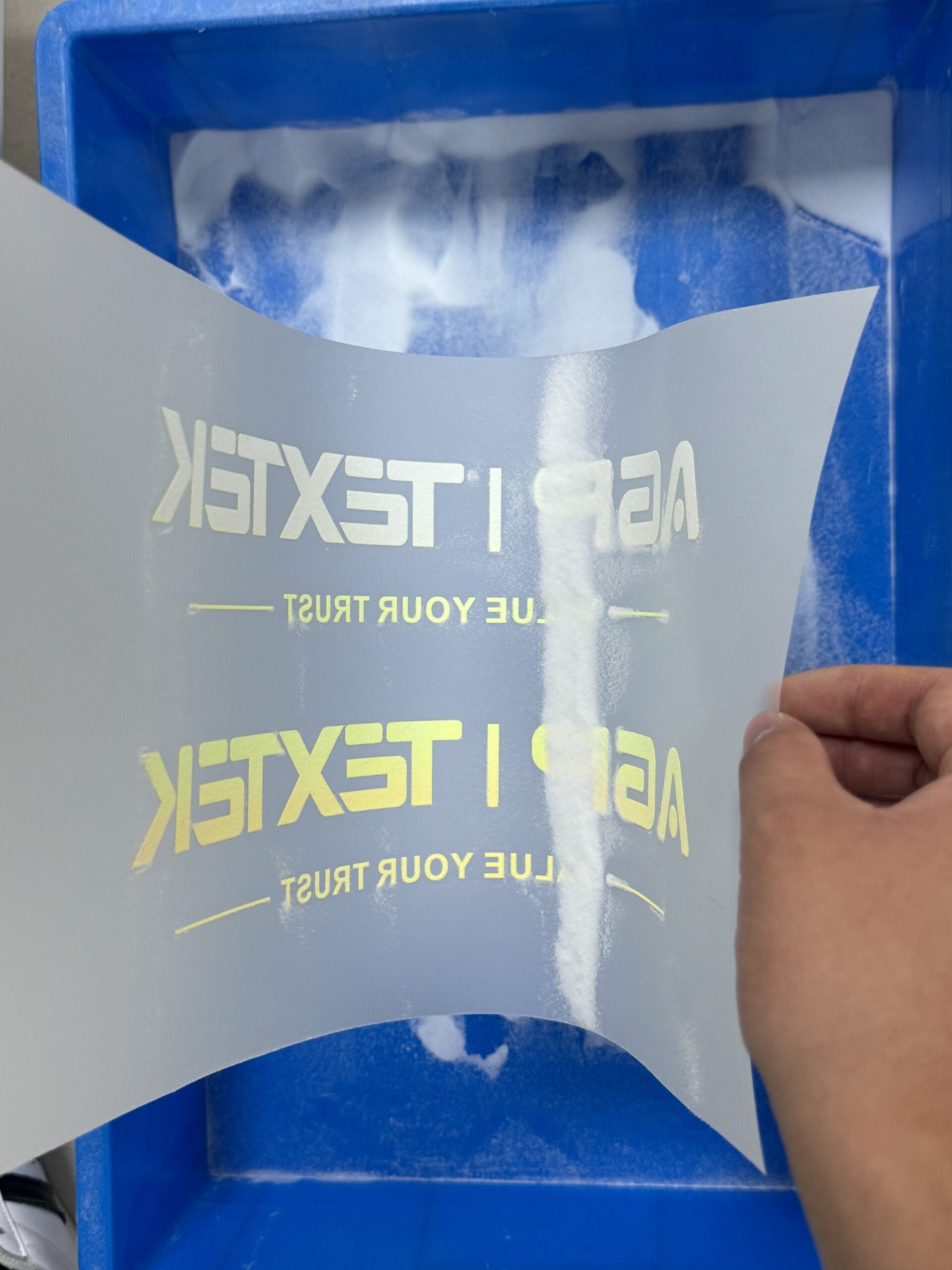

7. Cool and Peel the Film

Once heat pressing is complete, allow the undershirt to cool for a few seconds and then carefully peel off the transfer film. Most DTF fluorescent films require cold peeling. After cooling, peel the film off to view the bright fluorescent color pattern; the final product is bright and eye-catching.

Results Show

The final product shows the ultimate performance of fluorescent colors with vibrant colors and crisp pattern details, which are especially striking in the open air and under UV light. This printing method is not only suitable for tank tops, but can also be applied to a wide range of fabrics such as T-shirts, hats, backpacks, etc., thus greatly expanding the range of designs and applications.

Advantages of fluorescent color application

Eye-catching designs

Fluorescent ink is specially formulated to emit vibrant colors under normal light sources and works better under UV light. It is suitable for promotional apparel, team uniforms and event merchandise, etc., and can quickly catch the eye visually.

Various application programs

DTF fluorescent color transfer technology can be used in a wide range of fabric materials, be it cotton, polyester or blended fabrics, to achieve high quality prints with strong washable usability, thus ensuring that vibrant colors can be maintained for use after a long period of time.

High precision and clarity

DTF Fluorescent Transfer Technology enables high resolution pattern output, which is suitable for printing complex designs such as logos, detailed artwork or even photographs, meeting customer requirements for high quality patterns.

Conclusion

DTF Fluorescent Color Transfer Technology makes fluorescent colors stand out from fashion trends and become the highlight of sportswear, uniforms and promotional apparel designs. The intelligence and efficiency of DTF printers also make them essential in the customized apparel industry. With this scenario, we show how DTF fluorescent colors can spice up your products and help you lead fashion trends with ease.