How to Choose the Right DTF Transfer Hot Melt Powder for High-Quality Prints

Guide to Choosing the Right DTF Transfer Hot Melt Powder for Long-Lasting Prints

What is DTF Hot Melt Powder? DTF hot melt powder is a crucial material in the DTF (Direct-to-Film) transfer process, known for enhancing durability, flexibility, and visual clarity in prints. Available in coarse, medium, and fine grades, DTF hot melt powder can be chosen based on specific fabric needs, including cotton, polyester, or blended materials.

Guide to Choosing the Right DTF Transfer Hot Melt Powder for Long-Lasting Prints

What is DTF Hot Melt Powder? DTF hot melt powder is a crucial material in the DTF (Direct-to-Film) transfer process, known for enhancing durability, flexibility, and visual clarity in prints. Available in coarse, medium, and fine grades, DTF hot melt powder can be chosen based on specific fabric needs, including cotton, polyester, or blended materials.

Key Benefits of DTF Hot Melt Powder in Transfer Printing

- Enhanced Adhesion: Hot melt powder binds the pattern to the fabric, allowing for exceptional durability, even after repeated washes. This is vital for textiles like T-shirts and sportswear, where the design must withstand frequent use.

- Improved Pattern Durability: This adhesive layer strengthens the bond between the pattern and fabric, preventing issues like peeling or fading over time.

- Soft, Flexible Finish: High-quality hot melt powder ensures that the transferred pattern remains soft and elastic, so the garment feels comfortable.

- Optimized Heat Transfer Effects: Hot melt powder can create a clear, vivid finish, enhancing the pattern’s quality and visual appeal.

Choosing the Right DTF Hot Melt Powder: Key Factors to Consider

- Powder Thickness

- Coarse Powder: Ideal for dense fabrics like denim and coarse cotton.

- Medium Powder: Suitable for medium-weight cotton and polyester.

- Fine Powder: Works best for thin, delicate fabrics like T-shirts and sportswear.

- Mesh Count

- Fine powder with a high mesh count (80-200) is better for small details and fine fabrics, while lower mesh counts are best for thicker materials.

- Temperature Requirements

- High-Temperature Powder: Durable under high-temperature washing, suitable for items needing extra wash resistance.

- Low-Temperature Powder: Can be pressed at a lower temperature, making it convenient for heat-sensitive fabrics.

- Color of Hot Melt Powder

- White Powder: Common for most fabrics.

- Black Powder: Used on darker fabrics to prevent visible residue.

How DTF Hot Melt Powder Works in the DTF Process

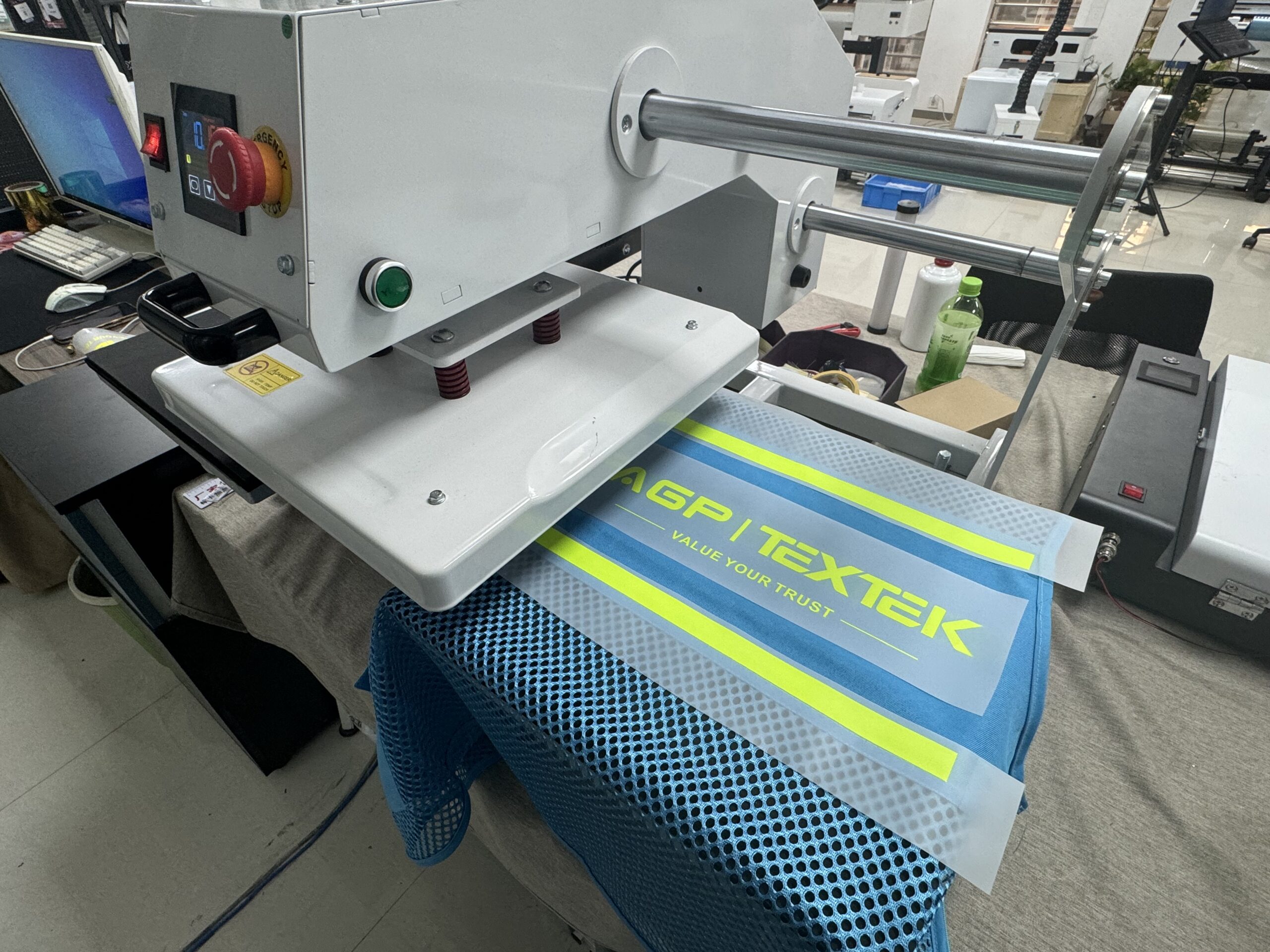

After a DTF printer prints the design with color, a white ink layer is applied. The hot melt powder is then evenly sprinkled onto the wet ink layer using a powder shaker. When the fabric is pressed with the heat press machine, the powder melts, bonding the design firmly to the fabric. This ensures a durable, vibrant transfer on various materials, from textiles to leather.

Additional Applications and Advantages of DTF Hot Melt Powder

Apart from DTF transfers, this powder is used for leather, wood, and paper prints. DTF hot melt powder is water-resistant, fast-drying, and eco-friendly, making it a versatile solution across industries.

Need Help Choosing the Right DTF Hot Melt Powder? We’re here to make your selection process easier. Get in touch with our experts to find the perfect DTF hot melt powder for your project!

#DTFPrinting #HotMeltPowder #TextilePrinting #DigitalPrintingSolutions #AGP