Innovative Foil Stamping Solutions: Seizing Market Trends Opportunities

Innovative hot stamping solutions combine modern technology and traditional craftsmanship to solve the problems of traditional methods. This solution uses advanced hot stamping equipment and special materials to achieve metallic luster while retaining the transparency and three-dimensional effect of the extended crystal mark. Finally, the implementation effects of the program are evaluated and forecasted, demonstrating its potential and advantages in improving product quality and market competitiveness.

In the ever-evolving field of printing technologies, foil stamping solutions are taking center stage, offering a new dimension of creativity and innovation to the printing industry. AGP, a leader in UV DTF and DTF Printing solutions, is excited to share insights into the world of foil stamping, specifically tailored for UV DTF Printers.

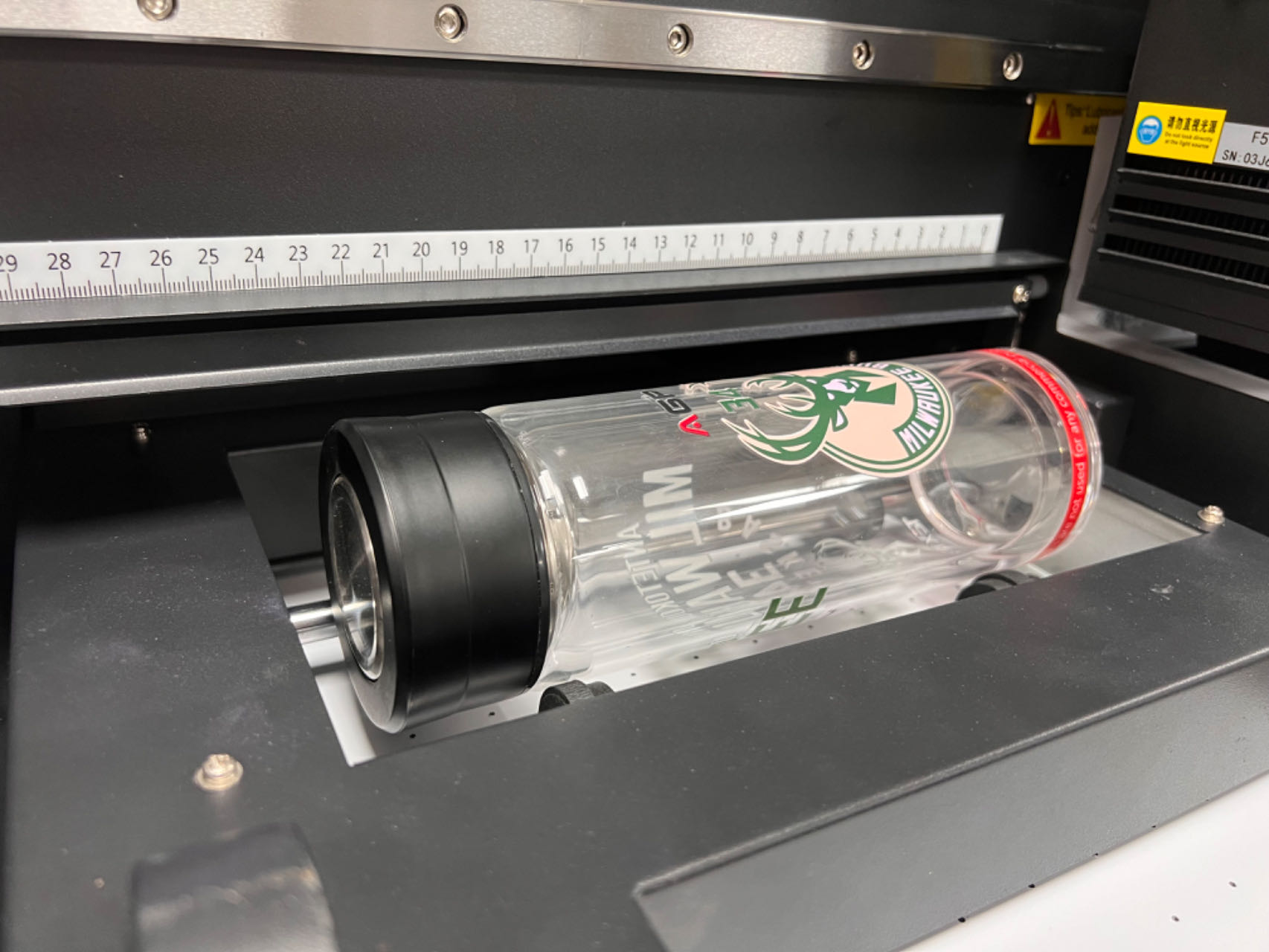

Foil stamping is a revolutionary printing process that transforms the visual appeal of crystal labels by applying a metallic foil effect, resulting in a unique and eye-catching luster. AGP is at the forefront of unraveling the potential of UV DTF Printers to achieve precise foil stamping effects. This not only adds personality to products but also elevates their overall visual impact.

Understanding the Two Main Foil Stamping Methods

1.Waste Discharge Solution:

Required Materials:

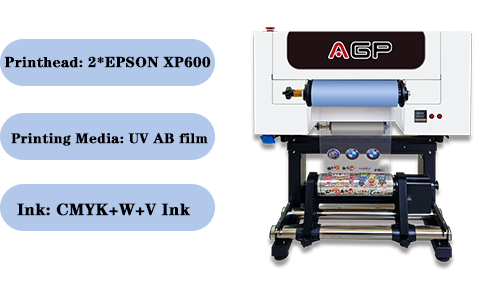

CMYKW+V (two varnish types)

Four kinds of films:A film,discharge film and golden/silver film,transfer film

Quantity of Print Head: 2Epson F1080 or 3Epson I3200-U1/I1600-U1.

Printing Process:

A film (paper feeder) – Printing(CMYKW+V) – Waste discharge film – Hot stamping – Coating (transfer film) – Finished product.

2.Glue Solution:

Required Materials: CMYKW+V (two varnish types) + Glue

Three kinds of films: Glassine Paper,gold/silver film,transfer film

Quantity of Print Head: 4*Epson I3200-U1/I1600-U1.

Printing Process:

Glassine Paper – Printing(CMYKW+V+G) – Hot stamping – Coating (transfer film) – Finished product.

AGP, with its focus on research and development, invites you to explore and share experiences and knowledge in the realm of UV DTF Printers and DTF Printing solutions.In the dynamic fusion of technology and creativity, foil stamping with UV DTF Printers opens doors to limitless possibilities. Let your products shine with a touch of brilliance, precision, and innovation!