Key factors affecting the printing effect of UV DTF printers

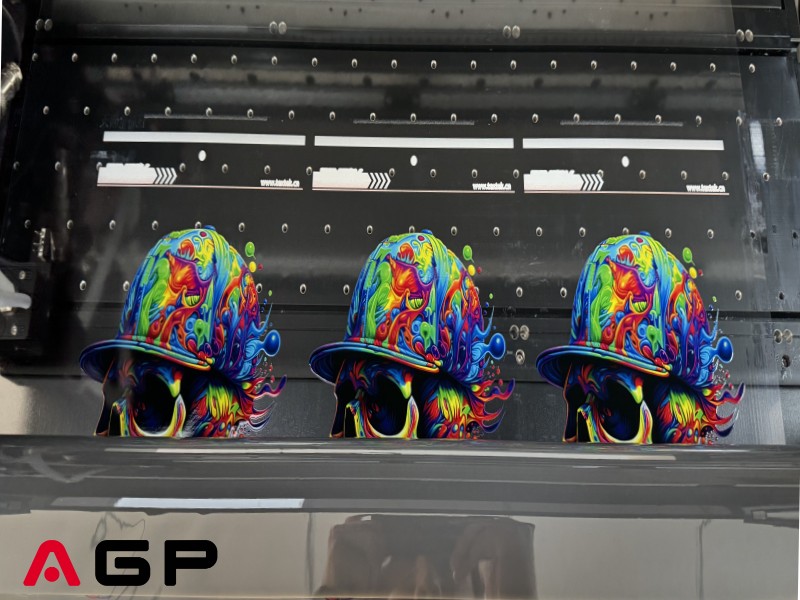

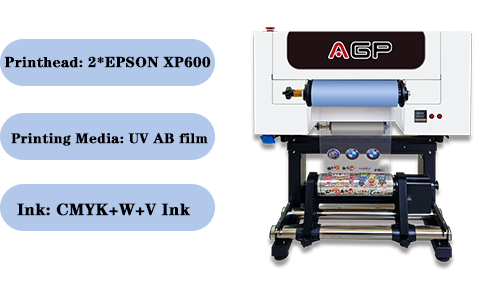

UV DTF printer is an important tool to enhance product performance, allowing your product to quickly enhance brand performance. UV DTF printer is an efficient and environmentally friendly printing device that uses UV ink to print and can quickly achieve high-quality printing on the surface of the printing film. The operation of UV DTF printer is simple and easy to master. The entire process is completed by UV DTF printer, and the finished product can be produced in 5 minutes. It is suitable for all types of users.

1. Choose the correct ink and printing film: The combination of different inks and printing films will directly affect the printing effect. It is recommended to conduct a small sample test when selecting ink and printing film to ensure that the printing effect meets expectations before mass production.

2. Optimize print settings: Print settings are the key factors affecting the printing effect. We need to reasonably adjust the print resolution, color management and other parameters according to the requirements of the work to achieve the best printing effect.

3. Regular maintenance of UV DTF printer: To ensure the stability and printing effect of UV DTF printer, regular cleaning and maintenance are required. At the same time, pay attention to check the ink remaining and replace the ink in time.