Maintenance methods for DTF printers that have been shut down for more than 48 hours

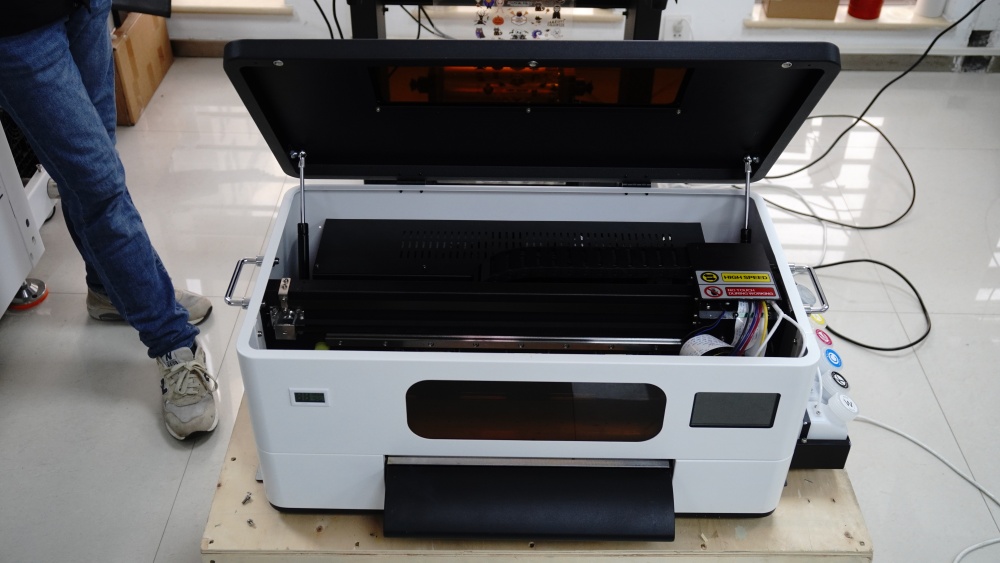

If your DTF printing equipment is not expected to be used for more than 48 hours, clean the ink in the printhead to prevent it from evaporating and drying up. In severe cases, excessive ink buildup can cause irreversible damage to the printhead, such as clogging.

Maintenance methods for DTF printers that have been shut down for more than 48 hours:

If your DTF printing equipment is not expected to be used for more than 48 hours, clean the ink in the printhead to prevent it from evaporating and drying up. In severe cases, excessive ink buildup can cause irreversible damage to the printhead, such as clogging.

To clean the printhead, follow these steps:

1. Turn off the power to the DTF printer and powder shaking machine.

2. Move the machine head to the leftmost cleaning position and place a corrosion-resistant container underneath to collect the cleaning waste liquid.

3. To clean the printhead, first remove it. Then, flush out the ink using a syringe and clean it with special moisturizing fluid. It is important to use the moisturizing fluid last, as residual cleaning fluid can corrode the printhead.

Once cleaned, place the printhead in a dry, corrosion-resistant container and seal it. To prevent the moisturizing liquid from drying out, seal the container tightly if it will be left unused for a week or more.

Check the mobile trolley and guide rails for stains and clean them promptly if any are found. The addition of further aspects must be avoided at all costs. Remove all non-essential fillers.

Avoid placing any items on the dtf printer to prevent potential damage or loss. Adhere strictly to metrics and units. The content of the improved text must be as close as possible to the source text. If the machine will be shut down for more than a week, cover it with a dust-free cloth to prevent excessive dust accumulation on the machine and its accessories.