Glass

With the development of science and technology, UV printing technology has shown strong application potential in several industries, especially in the field of glass printing.UV printers have become indispensable equipment in the decorative and advertising industry due to their high efficiency, environmental protection and high quality. In this article, we will delve into the application of UV printing on glass and its advantages.

UV Printing Technology Overview

UV printing technology uses ultraviolet light to cure the ink, enabling the ink droplets to quickly cure and mold on the surface of the media. This technology not only allows for printing on a variety of materials, but also allows for beautiful image effects. For high-density materials like glass, UV printing technology is particularly effective because its ink does not penetrate the interior of the media, ensuring the vividness and durability of the image.

UV printers are capable of printing rich colors at high resolution for a variety of occasions. Whether it's corporate logos, decorative artwork or home décor, UV printing can meet the diverse needs of customers.

Implementation of mirror printing

In glass printing, it is often necessary to perform mirror printing that is reversed and viewed from the front. The detailed steps of this process are as follows:

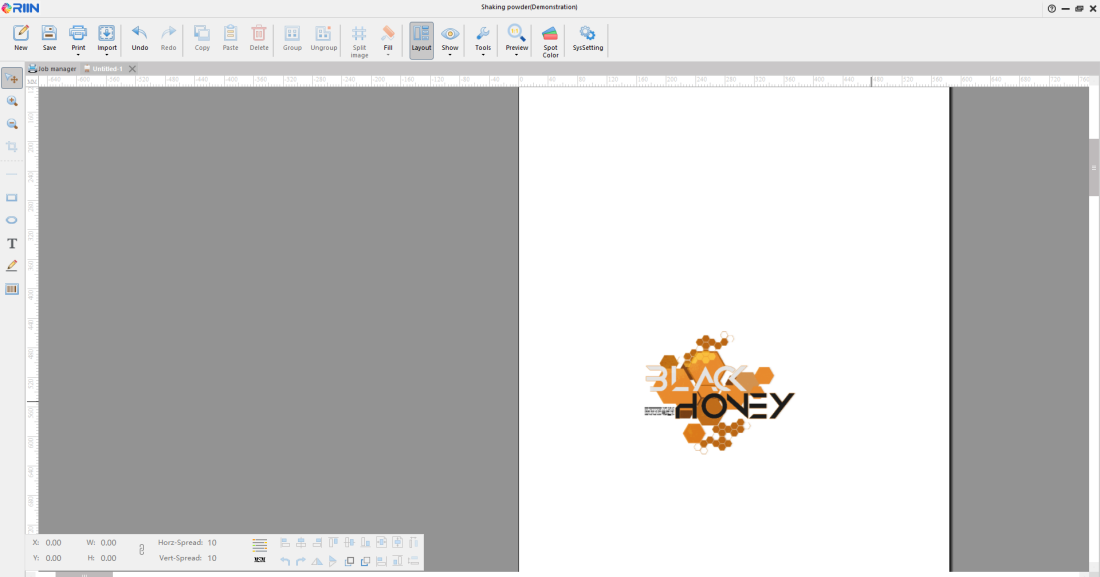

Image editing: Use software such as Photoprint on the computer to edit the designed image. Make sure that the resolution and color settings of the image meet the printing requirements.

Software settings: Select the "mirror printing" function in the print control software. This setting is required to ensure that the printed image is correct when viewed from the front of the glass.

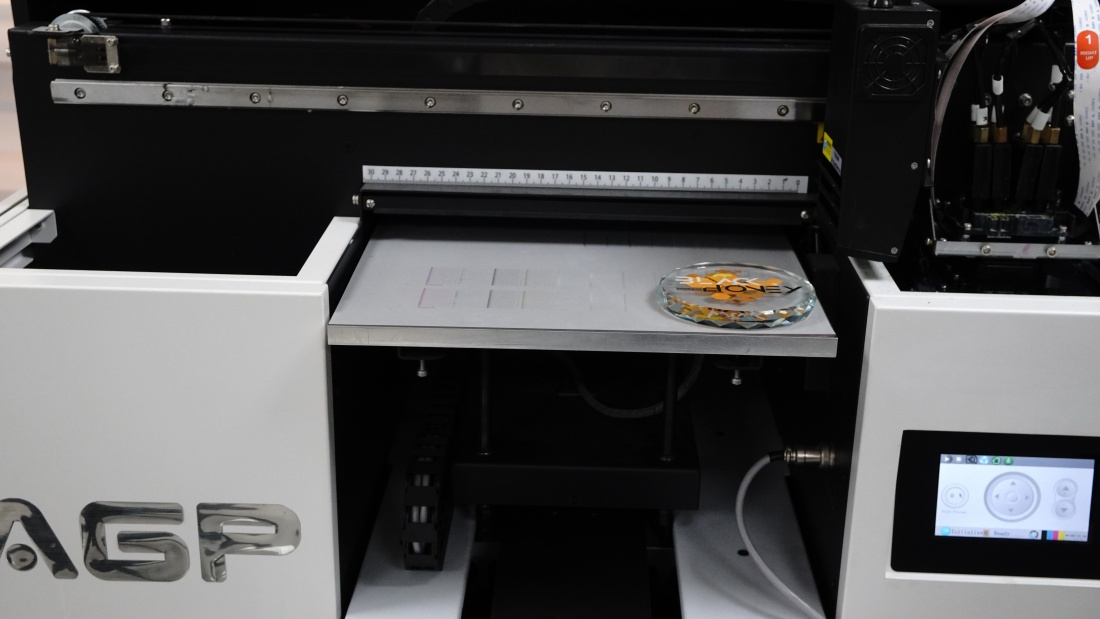

Place the glass: Place the glass to be printed steadily on the platform of the UV printer. Make sure it is fixed to prevent it from moving during printing.

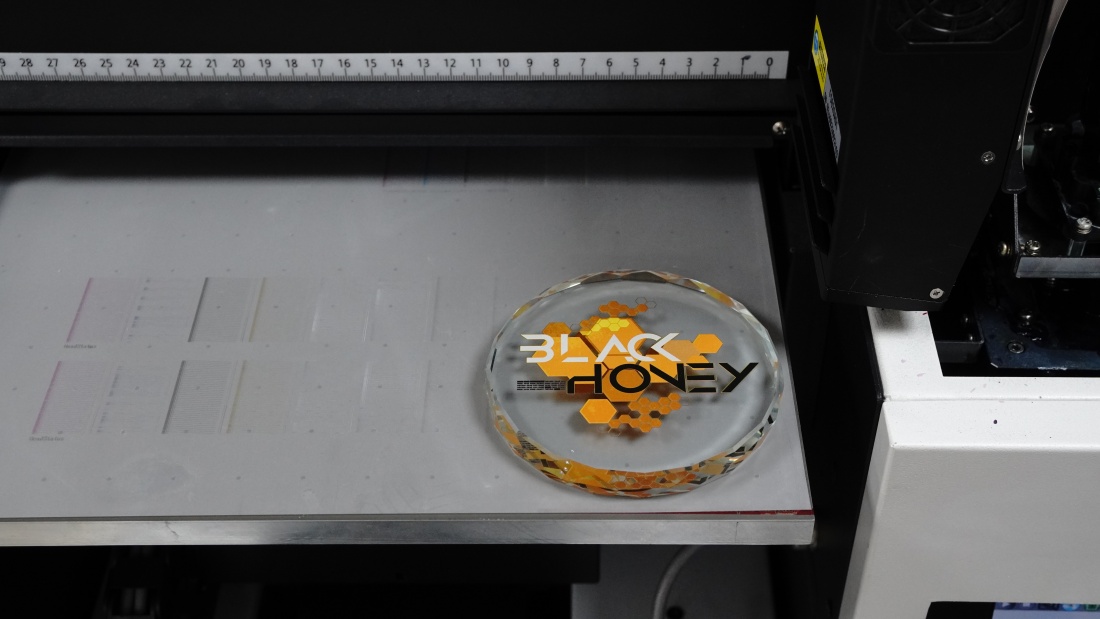

Start printing: Click the device to start and perform the printing operation. After printing is completed, the image on the glass will be clearly visible from the front.

This process ensures the accurate presentation of the image and is often used in applications such as advertising signs and display boards.

Necessity of coating treatment

Because the glass surface is smooth, the ink adhesion may not be ideal, so it is usually necessary to coat the glass before printing. This process can be divided into the following steps:

Cleaning the glass: Make sure there is no dust and oil on the glass surface, and use alcohol or special cleaner to clean it.

Spray coating: Use a spray gun and a compressor to spray the clear coat evenly. Usually spray twice to ensure uniform thickness and complete coverage.

Proper coating selection and processing methods are key factors in ensuring print quality.

Cost control strategies

When printing transparent materials, cost control is one of the top priorities for enterprises. The following methods can effectively reduce costs:

Reasonable settings: Choose the appropriate printing mode and nozzle settings to avoid blindly improving accuracy. Knowing the best settings for different materials can help optimize printing results.

Clean the surface of the material: Keep the surface of the printed material clean to reduce the scrap rate. Regularly check and maintain the printing equipment to ensure that it is in good operating condition.

Through these strategies, enterprises can not only improve production efficiency, but also increase profit margins.

Wide range of applications for UV printing

UV printing on glass has a wide range of applications, including but not limited to the following:

Decorations: personalized patterns and photos can be printed to increase the beauty of your home. For example, large artwork or family photos in the living room.

Advertising logos: Print corporate logos on transparent glass such as sliding doors and windows to enhance brand image. This type of application is commonly used in stores, tradeshows and corporate offices.

Artwork: print high-resolution artwork directly on glass to add an artistic atmosphere to the space. Suitable for art exhibitions and galleries.

Functional products: For example, customized printing of functional products such as non-slip glass and heat-insulating glass to meet market demand.

Advantages of AGP UV3040

Among many UV printers, AGP UV3040 stands out with its unique advantages. The device adopts advanced UV printing technology, with high-efficiency printing speed and excellent print quality, which can meet various glass printing needs. AGP UV3040 not only supports the printing of a variety of materials but also has excellent color reproduction ability and durability, to ensure that the print work is long-lasting and beautiful.