Safety Helmet

Enhancing Safety and Style: UV DTF Printing Revolutionizes Safety Helmet Customization

Safety helmets are critical protective gear in various industries, ensuring the well-being of workers in hazardous environments. While functionality remains paramount, the rising demand for personalization has led to the integration of UV DTF (Direct To Film) printing technology in safety helmet customization. This innovative printing method allows for vibrant and durable designs on safety helmets, combining safety with style. Let's explore how UV DTF printing is revolutionizing the way we personalize and enhance safety helmets.

1.Design and Preparation:

Begin by creating or selecting the desired design for the safety helmet. Ensure that the design aligns with safety regulations and requirements, incorporating necessary symbols, logos, or identification elements.Once the design is finalized, prepare it for printing using design software compatible with UV-F30.

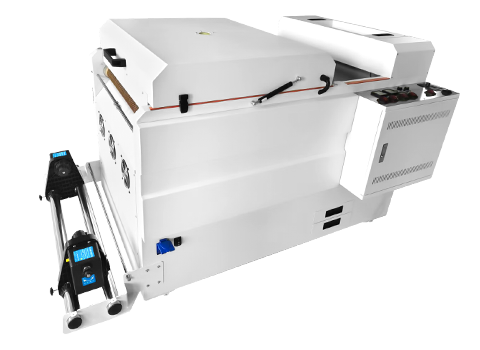

2.Prepare the UV-F30 Printer:

Ensure that your UV-F30 printer is properly set up and ready for printing. Follow the manufacturer's instructions for loading the UV DTF film and calibrating the printer settings. Make sure the printer is clean and free from any debris that could affect the print quality.

3.Print the Design:

Using the UV-F30 printer, print the design onto the UV DTF film. Ensure that the film is aligned correctly and securely attached to the printer's platen to avoid any misalignment during printing. Set the printer to the appropriate print settings for UV DTF film, including ink density, resolution, and curing time.

4.Cure the Printed Film:

After printing, carefully remove the printed UV DTF film from the printer. Place the film in a UV curing machine or under UV lamps to cure the ink. Follow the recommended curing time and temperature specified by the UV-F30 printer manufacturer to ensure proper adhesion and durability of the print.

5. Prepare the Safety Helmet:

Clean and prepare the surface of the safety helmet before applying the printed UV DTF film. Ensure that the helmet is free from dust, dirt, or any other contaminants that could affect the adhesion of the film.

6.Apply the Printed UV DTF Film:

Carefully position the cured UV DTF film onto the surface of the safety helmet. Smooth out any air bubbles or wrinkles using a soft cloth or squeegee, ensuring proper adhesion to the helmet's surface. Pay attention to aligning the design correctly with any pre-existing elements on the helmet.

7. Cure the Printed Film on the Helmet:

Once the UV DTF film is applied to the safety helmet, place the helmet in a UV curing machine or under UV lamps for the final curing process. This step ensures optimal adhesion and durability of the print on the helmet.

8.Quality Control and Inspection:

After the curing process, inspect the printed design on the safety helmet for any imperfections, misalignment, or issues with adhesion. Make any necessary adjustments or corrections to ensure a high-quality and visually appealing result.

UV DTF printing with the UV-F30 printer offers a seamless and efficient method for customizing safety helmets. By following the above steps, businesses can achieve vibrant and durable designs that enhance both safety and style. Embrace the power of UV DTF printing and elevate your safety helmets to new levels of safety, visibility, and customization, setting a new standard in the industry.