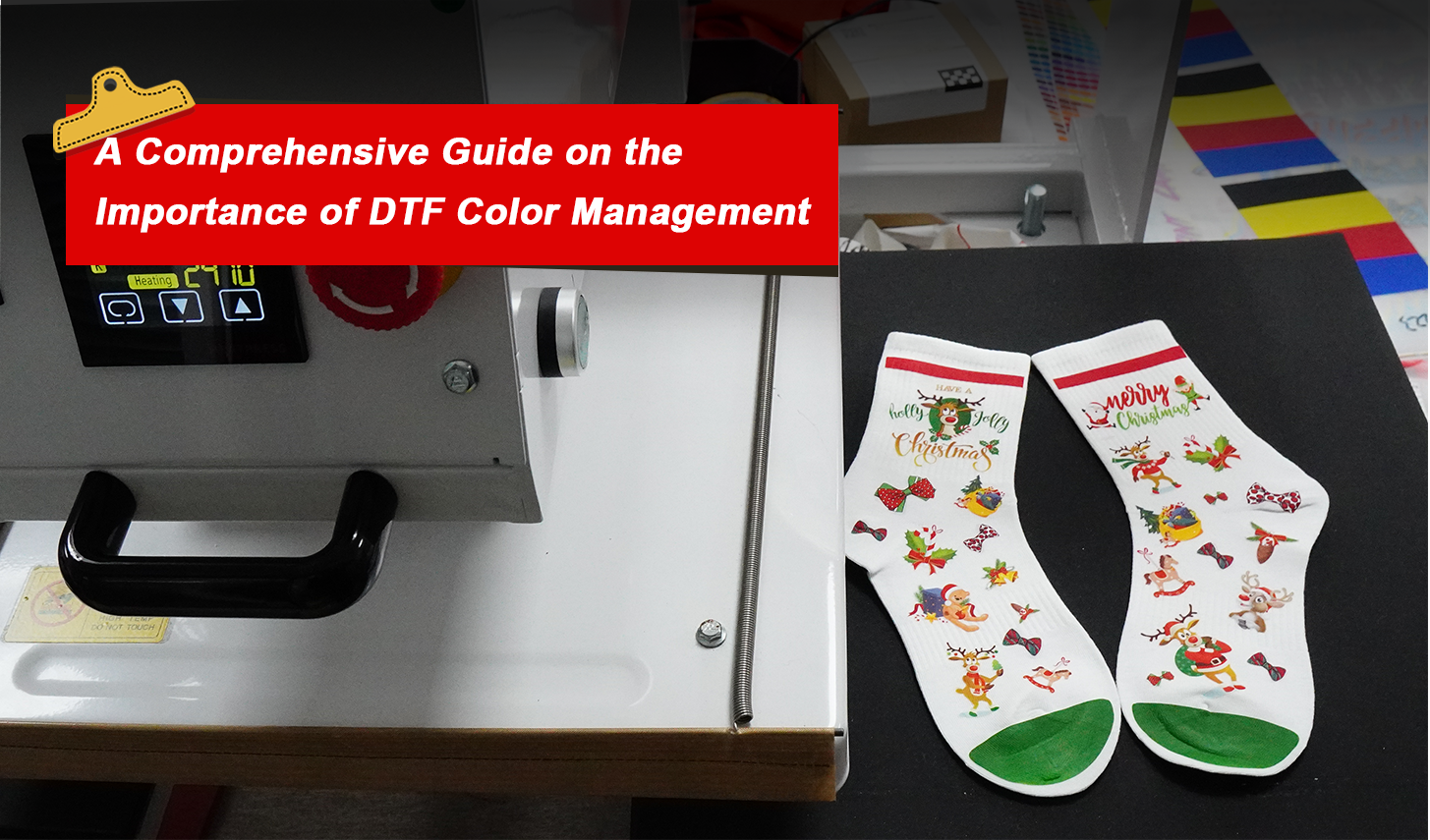

A Comprehensive Guide on the Importance of DTF Color Management

DTF printing is well known for its vibrant colors and intricate details. However, one cannot master the process without understanding the color management plan. By enhancing the color settings, you can boost the quality of your prints and make them memorable. DTF color management ensures consistency and high-end color reproduction throughout the whole project. The ultimate goal of this understanding is to make your design stand out.

The process involves how colors are interpreted and rendered by different devices, printer monitors, and other software applications. Businesses often use distinct approaches to resolve this issue. However, with basic techniques, they can overcome challenges like mismatched color, wasted material, and inconsistent results.

This guide will give you amazing insights into color management and its everyday challenges.

Color Challenges in DTF Printing

There are many common color challenges in DTF printing when it comes to color management. Let's discuss them in detail.

Mismatched Colors

Colors usually have varied thicknesses and mismatched consistency when mixed. Sometimes, improperly mixed inks can cause ink degradation.

Poor Ink Adhesion

If the ink quality is not good, you may face cracks and peeling prints, which can ruin the whole print. Ink adhesion is a very important component of DTF prints.

Bleeding Ink

You can encounter ink bleeding when the ink spreads out of the print area. As a result, the print becomes blurry and messy.

White Ink Complexity

White ink is difficult to manage, and it can especially cause uneven coverage, which can negatively impact print quality.

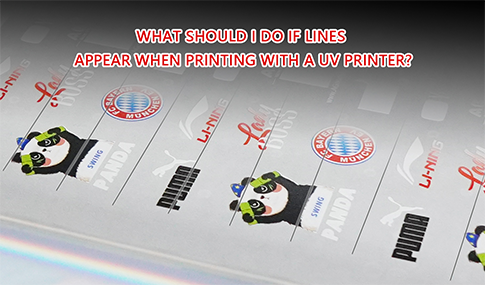

Clogged Print Heads

Sometimes, printer heads are clogged or prints are lined. It ruins the print; sometimes, a single line causes an abrupt print.

DTF Color Management Key Steps

When you are looking for a successful DTF color management, it depends on understanding several key components.

Every little component contributes a lot to a consistent workflow. Learn all the components to optimize your print quality and colors.

1. Equipment Calibration

All the devices involved must have the same settings. Properly calibrated monitors and printers will reduce discrepancies. Settings are vital for standardized color profiles to have the same result on all devices. Moreover, the RIP software has ink settings, resolution, and color mapping. The software then lets the system communicate well with color information.

2. Color Profiles

ICC (International Color Consortium) profiles are used as the universal language of colors between various devices, enabling consistent color communication. ICC profiles can turn digital designs into vibrant, high-resolution prints.

3. Color Spaces

Color spaces are of two types; input color space defines the range of colors in the accrual design. It is typically in RGB or Adobe RGB. Meanwhile, the output color space determines how printers interpret colors and guarantees fidelity in color production.

4. Media Calibration

When something is about media, it involves different settings based on the type of film or substrate that ensures the exact application of color. In this process, ink density is controlled, temperatures are curing after heat press, and other variables are vital in maintaining print quality.

5. Quality Control

Complex and aesthetic prints require lots of regular test prints and recalibration to maintain consistency across production runs and make them smooth.

Following these key considerations, one can maximize the overall output of the print and its quality.

Color Consistency and Quality Control

Color management is a structured framework that smooths the overall process. The workflow is symmetrical, which means the layers are layered on each other with a consistent flow. Color consistency and quality control depend upon different components, as mentioned above. However, quality control involves many management processes.

Use the Correct Color Mode

DTF printing uses three primary color modes: RGB, CMYK, and LAB. CMYK is the most common color mode, including DTF transfer.

Accurate Color Profile

Just like modes, color profiles are vital. They tell how the color should behave and display throughout the process.

Calibrated Monitor and Printer Devices

Calibrated devices ensure maximum output with excellent efficiency.

Test the Soft Copy

Before taking the final prints, ensure the color is the same as captured. You can preview them during the design editing phase. It helps to reduce waste.

Test Print

Once prints are ready, they must be checked for color accuracy. Any mismanagement of colors helps improve the quality of designs.

Consider Environmental Conditions and Surroundings

Weather conditions play a significant role in the design prints. Be aware of environmental conditions that may affect the color density and overall drying time of the ink. This also includes the time required for the heat press during DTF prints.

Use Color Management Software

It can help you manage color consistency and quality control.

DTF printing is one of the most used technologies, offering color accuracy and durability. Proper color management is vital for prints to last longer.

Why Is Color Management Essential in DTF Printing?

DTF color management is an important factor in the success and profitability of your prints. Let's discuss why it is essential.

The exact accuracy of colors in various devices

Devices interpret color according to their resolution and other factors. Effective color management is necessary to interpret the same colors in different devices. It is essential because the same color will be used for your print.

Same Consistency in Various Projects

Consistency is a crucial component in building credibility. If the prints are uniform, it means repeated orders will have the same accuracy of designs.

Enhanced Efficiency

If the colors are not managed properly, they may be skewed, wasting ink. Proper management can enhance efficiency and reduce the chances of errors.

Satisfied Customer Experience

Customer experience is the pillar that tracks the success of your project. With proper management, customer expectations can be met. Ultimately, the customer relationship will be strengthened,

Versatile Application Options

DTF printing supports multiple fabrics and substrate types, all of which interact with ink differently. Color management has varied options for distinct materials, ensuring the high quality of the print.

Conclusion

DTF prints are the ultimate source of high-quality colors. However, maintaining the quality of the prints is a bit complex task. It could be achieved effectively with a color management plan. Once you master color modes, spaces, and methods, DTF prints can be meticulously fine-tuned. To make your print stay longer, printer calibrations must be regular. These factors can improve your DTF printing experience and enhance prints' longevity.