By doing these things, your DTF printer failures will be reduced by 80%

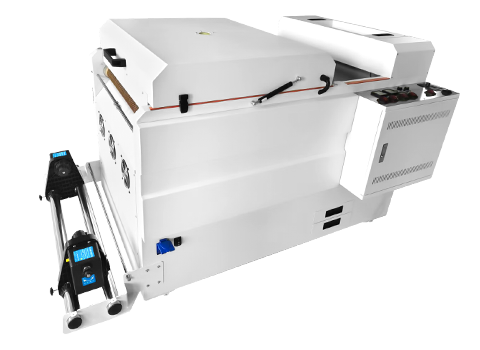

If a worker wants to do his job well,he must first sharpen his tools.As a new star in the textile printing industry, DTF printers are popular for their advantages such as "no restrictions on fabrics, easy operation, and bright colors that do not fade." It has low investment and quick return. In order to continue to make money with DTF printers, users need to do daily maintenance work to improve equipment integrity and utilization and reduce downtime.So today let us learn how to perform daily maintenance on the DTF printer!

1. Machine placement environment

A. Control the temperature and humidity of the working environment

The working environment temperature of the printer equipment should be 25-30 ℃; the humidity should be 40%-60%. Please place the machine in a suitable space.

B. Dustproof

The room must be clean and dust-free, and cannot be placed together with equipment that is prone to smoke and dust. This can effectively prevent the print head from clogging and prevent dust from contaminating the printing layer in progress.

C. Moisture-proof

Pay attention to moisture-proofing the working environment, and close vents such as doors and windows in the morning and evening to prevent indoor moisture. Be careful not to ventilate after cloudy or rainy days, as this will bring a lot of moisture into the room.

2. Daily maintenance of parts

The normal operation of DTF printer is inseparable from the cooperation of accessories. We must perform regular maintenance and cleaning to keep it in the best working condition so that we can print high-quality products.

A. Print head maintenance

If the device is not used for more than three days, please moisturize the print head to prevent drying and clogging.

It is recommended that you clean the print head once a week and observe whether there are any debris on and around the print head. Move the carriage to the cap station and use a cotton swab with cleaning fluid to clean the dirty waste ink near the print head; or use a clean non-woven cloth dipped in cleaning fluid or distilled water to wipe off the dirt on the print head.

B. Movement system maintenance

Add grease to gears regularly.

Tips: Adding an appropriate amount of grease to the long belt of the carriage motor can effectively reduce the working noise of the machine!

C. Platform maintenance

Keep the platform free of dust, ink, and debris to prevent scratches on the print head.

D. Cleaning and maintenance

Check the cleanliness of the guide rails, wipers, and encoder strips at least once a week. If there are any debris, clean them and remove them in time.

E. Cartridge maintenance

In daily use, please tighten the cap immediately after loading ink to prevent dust from entering.

NOTE: Used ink may clump on the bottom of the cartridge, which may prevent smooth ink output. Please clean the ink cartridge and waste ink bottle regularly every three months.

Precautions for daily use

A. Choose high-quality ink

It is recommended that you use original ink from the manufacturer. It is strictly forbidden to mix ink from two different brands to avoid chemical reactions, which may easily block the print head and ultimately affect the quality of the finished product.

Note: When the ink shortage alarm sounds, please add ink in time to avoid sucking air into the ink tube.

B. Shut down according to prescribed procedures

When shutting down, first turn off the control software, then turn off the main power switch to ensure that the carriage returns to its normal position and that the print head and ink stack are properly connected.

Note: You need to wait until the printer is completely shut down before turning off the power and network cable. Never unplug the power supply immediately after shutting down, otherwise it will seriously damage the printing port and PC motherboard, resulting in unnecessary losses!

C. If you have any questions, contact the manufacturer promptly

If a malfunction occurs, please operate it under the guidance of an engineer or contact the manufacturer directly for after-sales assistance.

Note: The printer is a precision device, please do not disassemble and repair it by yourself to prevent the fault from expanding!