Combine UV Printer and Laser Engraver | A Combination to Make More Money

Combining UV Printer with Laser Engraver could be your game-changer if you're looking for new directions to improve your business. It is perfect for companies starting a customizing project, already-existing companies trying to improve their product line, or manufacturers looking to internalize manufacturing in order to simplify operations.

Two modern technologies working in concert not only extends your creative vistas but also increases operational efficiency. Accept this creative strategy to watch your company flourish by providing outstanding, customized products that are unique on the market.

Overview of UV Printers and Laser Engravers

UV printers and laser engravers are essential instruments in the field of digital fabrication. They both have special features to meet different creative requirements.

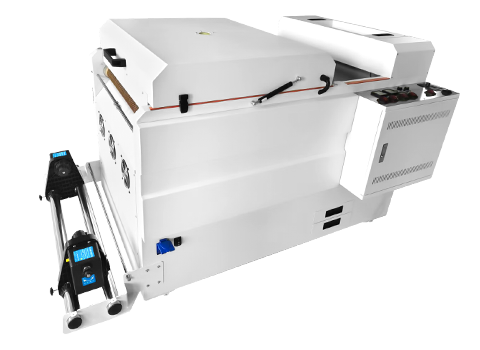

A UV Printer operates by curing or drying of the ink upon contact with the medium utilizing UV light. In this way, it allows printing on a variety of materials, including metal, glass, and plastic. This technique increases the options for product personalizing. Colors are vivid and details are sharp using a UV printer, so guaranteeing excellent finishes on both flat and rough surfaces.

Conversely, laser engravers etch designs into several materials using a high-powered laser beam. This method is exact, enabling easy creation of complex patterns and minute details. Laser engravers perform effectively on materials including wood, acrylic, leather, and even soft metals. The method is perfect for mass-manufacturing uniform, repeatable designs as much as for producing complex artwork or text.

Eventually, for companies trying to innovate, both instruments have transforming power. They allow new directions for product development. They also provide great material and application flexibility, and enable fast manufacture. Including a Laser Engraver and a UV Printer into your process will help you greatly improve the range and quality of goods you sell.

The Benefits of UV Printing and Laser Engraving

UV Printing and laser engraving together offer a powerhouse of advantages. These benefits will change the entire landscape of your business. Both of these technologies offer unique benefits, which taken together provide a strong basis for innovation and creativity. So, without any further ado, let’s dive in the benefits of this combination:

UV Printing Advantages:

- Versatility: Plastics, metals, ceramics, even glass are among the several materials UV printers shine in handling. This adaptability lets companies easily grow their product line.

- Speed and Efficiency: Under UV light, the ink dries almost instantly with UV printing, therefore greatly accelerating manufacturing times. Faster turnaround for orders made possible by this quick curing technique increases output.

- Durability: UV printer creates shockingly robust prints. Ideal for both indoor and outdoor uses, the UV-cured inks withstand fading, weather, and water.

- High-Quality Detail: With high resolution and vivid colors, UV printing presents extraordinary print quality. This makes it ideal for works needing rich colors and minute details.

Laser Engraving Advantages:

- Precision: Unmatched precision made possible by laser engraving lets one create elaborate designs too difficult for conventional techniques. Creating fine text, complex patterns, and precise logos calls for this accuracy.

- Consistency: Laser engravers deliver consistent results on every object. Maintaining quality across big quantities of products depends on this uniformity.

- No Contact: Laser engraving removes the possibility of material distortion or damage since it does not involve direct touch with the object. For sensitive or delicate materials especially, this non-contact approach is quite helpful.

- Customization Opportunities:For limited edition items or customized orders, laser engraving is perfect since it allows products in little quantities to be readily changed.

Businesses who combine UV printing and laser engraving not only improve their operational capacity but also their market flexibility. This mix opens up new markets. Additionally, it lets a larger audience enjoy a seamless blending of quality, durability, and customizing. Using these technologies, businesses may provide services that really stand out. Thus they meet and surpass consumer expectations in a market of competition.

How UV Printing and Laser Engraving Complement Each Other?

Two separate technologies that really go well together are UV printing and laser engraving, which lets companies increase their product offers and creative frontiers. Both forms of technology offers special advantages that complement one another and help to offset any restrictions.

Complementary Nature of UV Printing and Laser Engraving:

- Material Versatility: Although laser engravers specialize in producing texture and depth, UV printers shine in adding color and detail to a variety of surfaces. A company might etch a precise pattern into a wooden plaque using a laser engraver, for instance, then add vivid, colorful images or text to the same piece using a UV printer. This mix lets one create visually arresting, haptic multi-dimensional items.

- Enhanced Product Durability and Aesthetics: Items that will be subjected to heavy handling depend on a weather or fade-resistant finish offered by UV printing. Combining the accuracy cuts and marks of a laser engraver with these results produces a product that is not only aesthetically pleasing but also durable.

For outdoor signage, custom furniture, and personalized gifts especially, this double enhancement can be quite helpful.

- Streamlined Production Processes:Combining UV printing and laser engraving helps to simplify manufacturing procedures. Using both approaches on one product will help companies cut handling and setup times across several production phases.

Faster completion of challenging tasks resulting from this integration helps to maximize both time and labor resources.

- Creative Flexibility: The capacity to alternate between two technologies opens manufacturers' and designers' creative opportunities. They can play about with several effects. These include mixing printed colors with carved textures to provide distinctive visual contrasts. In markets when uniqueness and customizing are highly prized, this adaptability is very helpful.

- Market Expansion: Offering products that combine UV printing and laser engraving will help companies appeal to a wider market. Products that satisfy both appearance and utility often appeal to more people, therefore reaching consumers in sectors ranging from premium custom items to promotional goods.

Step-by-Step Guide: Combining UV Printing and Laser Engraving

Combining UV printing with laser engraving into a single workflow will greatly improve the utility and appearance of your products. This is a brief, detailed manual for properly combining various technologies:

Step 1: Design Preparation

Start with a clear design specifying which elements of the product will be engraved and printed. Use design tools fit for UV printers and laser engravers.

Step 2: Material Selection

Select materials like wood, acrylic, or covered metals that fit for laser engraving as well as UV printing. Verify the thickness and qualities of the material match those of both machines.

Step 3: Laser Engraving First

Begin with the laser engraving process. This lets you precisely cut, etch, or deep-engrave without changing the printed design. The material and depth of the engraving needed will guide your laser settings.

Step 4: UV Printing

Start UV printing after the engraving is finished. Direct addition of vibrant graphics or finely detailed images by the UV printer can cover the remaining blank spaces or the etched sections. Make sure the print settings are ideal for the material to get vivid and long-lasting hues.

Step 5: Finishing Touches

Once printed, let the product cure if needed to guarantee a complete set of the inks. Add any finishing treatments required to improve product visual impact and longevity.

Step 6: Quality Check

At last, carefully inspect the printed and engraved pieces' alignment, clarity, and durability. Ensure that they satisfy your needs.

Conclusion

Combining UV printing with laser engraving creates a world of possibilities. This lets companies provide not just one-of-a-kind but also quite durable and customized goods. Adopting these technologies can help you to meet a varied market and improve product quality. This greatly increases your profitability.

This guarantees production efficiency while also allowing design to be creative and innovative. Remember that the secret to success is to know the possibilities and constraints of every technique. This is how you completely maximize their potential in harmony as you investigate the strong mix of UV printing and laser engraving.