DTF vs. DTG Printing: Choose The Right Printing Method

DTF vs. DTG Printing: Choose The Right Printing Method

With so many new printing methods around, the DTF vs. DTG printing debate has sparked — and let's just say the decision is HARD. Both printing methods have pros and cons, so how do you make the call?

Imagine spending time and resources on a printing method, only to realize that wasn't what you wanted. The texture feels off and the colors just aren't vibrant enough. One wrong decision and you're sitting on a pile of unwanted goods.

Don't you wish someone would point you in the right direction from the beginning? Here's everything you need to know to decide between DTF vs. DTG printing.

What is DTG Printing?

As the name suggests, direct-to-garment printing involves ink spraying directly onto a cloth or garment. It works similar to a regular inkjet printer but replaces the paper with cloth and the oil-based inks with water-based ones.

Direct-to-garment printing is great for custom designs and works best on natural materials such as cotton and bamboo. The best thing about DTG printing is detailed and vibrant designs that won’t fade away despite however many washes.

How Does DTG Printing Work?

DTG printing is relatively straightforward, as compared to other printing techniques. You start by creating or selecting a digital design supported by the DTG printing program. Next, apply the pre-treatment, which allows the ink to bond with the fabric rather than sink in.

Your garment of choice is then mounted on a platen, fixed in position, and sprayed on with ink. Once cured, the procedure is complete and the garment is ready for use. Benefits of DTG printing include minimal set-up time and significantly lower production costs.

What is DTF Printing?

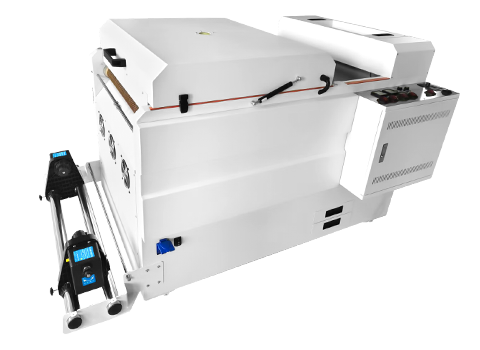

As compared to other printing methods, direct-to-film (DTF) printing is a relatively newer method. DTF printing requires a special transfer film and a heat press.

DTF printing works best on materials such as polyester, treated leathers, 50/50 blends. However, it may be incredibly difficult on dark colors such as blue and red.

How Does DTF Printing Work?

Once you’ve decided on a custom design, and it’s printed onto the transfer film, it's treated with a thermo-adhesive powder. The thermo-adhesive powder allows the design to bond with the fabric under the heat press. Once the water-based ink has cured and cooled, the film is carefully stripped away to reveal a vibrant design.

DTF vs. DTG Printing: What Are The Differences?

DTF and DTG printing both require digital art files to be transferred to the inkjet printer. However, that’s about it — apart from this, it’s all different.

Here are some of the major differences between the two printing techniques:

Quality and Aesthetic

While both DTF and DTG printing techniques offer great print quality, DTG printing is a poor choice if you've decided to go for a dark color. If you’re printing detailed or intricate designs such as fine art, for example, DTF printing is a clear winner.

Cost and Efficiency

Cost plays an important role when discussing the DTF vs. DTG printing debate. Although the costs for DTF and DTG printers run parallel, you're looking at greater ongoing investments for aqueous inks for DTF printing.

Fortunately, though, if you partner with a print-on-demand company, your upfront investments can be zero!

Durability and Maintenance

The good news is that both printing techniques are durable, but DTG prints may require extra care to withstand multiple washes.

DTF prints, on the other hand, are smooth, elastic, built for heavy use, and resistant to cracking.

Production Time

While DTF printing may seem a little complicated because it requires the extra step of printing on a transfer film first, it's the faster of the two.

Unlike DTG printing, DTF printing requires only one round of curing, which is further sped up by the heat press. DTG prints are usually dried using an air dryer, which takes longer.

Which One Should You Choose?

Both printing techniques offer brilliant results — in their ways.

Direct-to-film printing is your go-to if you're printing on synthetic materials and require vivid and sharp designs. Not for large pictures though. DTF prints aren't breathable, so the bigger the picture, the more uncomfortable the wear. This of course isn't a problem if you're printing on hats or bags.

Printing on natural materials and your designs aren't too complicated? DTG printing is your best bet. DTG printing is perfect if you want to flaunt your logo — the trade-off, however is that the designs are aren't as sharp.

So, DTF vs. DTG printing? It's your pick.

Frequently Asked Questions

What Are The Disadvantages Of DTF Printing?

If you’re printing large designs, DTF printing isn't a good option. Especially since these prints aren't breathable, large graphics tend to make clothing uncomfortable to wear for long periods.

Do DTF Prints Crack?

DTF printing is resistant to cracking. To make sure they last you a while, you should ideally wash them in cold water and avoid ironing on top.

Which is Better, DTF or DTG?

The 'better' choice ultimately depends on your requirements. To make the best choice, make sure you weigh out the pros and cons.