From Advertising to Art: How UV Printing is Redefining Industry Standards

Remember the days when printing meant waiting hours—sometimes days—for ink to dry, hoping the colors didn’t bleed, and being limited to just paper? Those days are long gone. Thanks to the rapid development of UV printing technology, we're now in an era where creativity meets speed, quality meets versatility, and eco-friendliness meets industrial-grade performance.

From personalized gifts and marketing displays to luxury packaging and even product prototyping, UV printing is reshaping industries one print at a time.

Let’s dive into this vibrant world and explore three revolutionary UV printing applications that are changing how we design, manufacture, and deliver value.

What is UV Printing?

Definition and How It Works

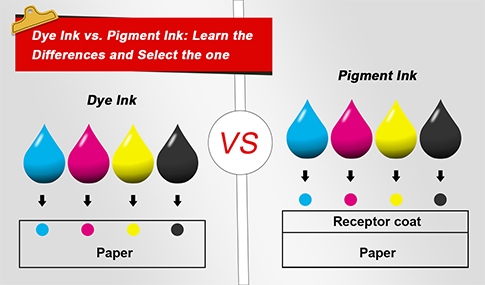

UV printing is a digital printing method that uses ultraviolet light to instantly cure or dry the ink as it's being printed. Instead of soaking into the surface, the ink sits on top and hardens immediately, giving you sharper, more vibrant results.

Key Components: UV Ink and UV LED Lamps

-

UV Ink: Specially formulated to solidify when exposed to UV light.

-

UV LED Lamps: Instantly cure the ink mid-print, eliminating drying time.

How UV Differs from Traditional Printing Methods

Traditional printing requires heat or air drying, longer production time, and is often limited by material type. UV printing, on the other hand, is:

-

Instant-drying

-

Versatile across surfaces

-

More environmentally friendly

Core Advantages of UV Printing

Instant Drying and Fast Turnaround

Print today, ship today. No more 3-day drying windows or expensive lamination.

All-Material Compatibility

Plastic, metal, leather, wood, acrylic, ceramic—you name it. UV prints on almost anything, so no pre-treatment is needed.

Eco-Friendly and Energy-Efficient

No harmful solvents. No ozone emissions. Just clean, efficient printing.

High Durability and Outdoor Resistance

UV prints are UV-resistant, waterproof, scratch-resistant, and can last over 3 years outdoors.

Application Solution 1 – Large-Size Flat Printing

Why Speed Matters in Advertising and Signage

When events are around the corner or promotional campaigns go live, turnaround time is critical. That’s where UV printing wins with instant curing and high-speed output.

Common Applications

-

Billboards

-

Car wraps

-

Light box panels

-

Exhibition walls

Case Study: AGP UV-S1600 Roll-to-Roll Printer

Efficiency Boost with Full-Page Printing

This 1.6-meter wide beast prints full-size graphics without splicing, eliminating misalignment issues and dramatically cutting delivery time.

Weather Resistance and Vivid Color for Branding

UV-S1600’s vivid output ensures your branding pops and lasts, rain or shine. It's built to handle urgent, large-scale ad jobs with ease.

Application Solution 2 – Relief Printing

The Power of Touch and Texture

Imagine holding a wine box where the logo is raised in elegant gold foil, or a painting where the brushstrokes feel real. That’s relief printing—adding texture that engages not just the eyes, but also the fingertips.

Common Applications

-

Art reproductions

-

Braille signage

-

Luxury gift packaging

-

Premium product labels

Case Study: AGP UV6090 Printer

3D Texture Without Manual Engraving

Forget hours of handwork. UV6090 stacks ink in precise layers, simulating embossed effects in minutes.

Artistic Reproduction with High-End Feel

From antique art to modern packaging, this printer handles it all with finesse and unmatched detail.

Application Solution 3 – Curved Surface Printing

Printing on Bottles, Gadgets, Curved Objects

UV printers can adjust to the shape of the object, allowing 360° printing on:

-

Water bottles

-

Cosmetic containers

-

Bluetooth speaker shells

-

Curved acrylic signage

No Transfer Films, No Screen Printing Hassles

Just load the item, adjust the software, and print. No messy setups or waste.

Case Study: AGP UV3040 Multifunction Printer

Supports Flat, Roll, and Cylindrical Printing

This compact yet powerful unit handles everything from keychains to mugs to tubes.

Ideal for Multi-Material, Small-Batch Jobs

Perfect for prototyping, promotional products, or artisanal branding, especially when quick customization is needed.

Why More Businesses Are Switching to UV

Flexibility in Design and Production

Need a one-off? No problem. Need a thousand identical units? Just as easy.

Short Lead Times for Personalized Items

Serve the growing demand for personalization with same-day delivery options.

Lower Cost in Long-Term Production

Fewer processes. Less waste. Lower labor. That’s savings you’ll feel.

UV Printing Across Industries

Industrial Manufacturing

Durable, scratch-resistant coding and labeling on parts, tools, and machinery.

Artistic Creation

Print on canvas, wood panels, or even stone for fine-art reproductions.

Custom Gifts and Promotional Items

Phone cases, keychains, pens, bottle openers—you can print directly onto them all.

Electronics and Smart Device Accessories

UV printers work wonders on plastic, silicone, and coated glass. Perfect for startups and niche electronics brands.

Final Thoughts – Print the Future

UV printing is more than just ink on a surface—it’s a creative tool, a business accelerator, and a sustainability solution all in one. Whether you're trying to stand out in the advertising world, craft beautiful packaging, or bring a personal touch to your product line, UV printing is the future-ready solution you've been looking for.

So, are you ready to print beyond the limits?

Conclusion

With the fast evolution of digital printing, UV technology has firmly established itself as the go-to printing solution across industries. From lightning-fast billboards to luxurious textured prints and intricate cylindrical designs, it opens the door to creative, durable, and sustainable production. Whether you're a business owner, designer, or manufacturer, it's time to harness the power of UV and bring your ideas to life—brilliantly, boldly, and efficiently.

FAQs

1. Can UV printing be used on metal?

Absolutely. UV printing adheres well to metal surfaces like aluminum, stainless steel, and coated metals without any pre-treatment.

2. Is UV printing waterproof?

Yes. UV inks cure into a solid, making the print water-resistant, smudge-proof, and ideal for outdoor use.

3. What’s the difference between UV and DTF printing?

UV printing is suitable for rigid and curved surfaces, while DTF (Direct-to-Film) is more suitable for fabric and garment printing. Each has its unique strengths.

4. How durable is UV printing for outdoor use?

Extremely durable. UV prints can last 3+ years outdoors, resisting UV rays, rain, and abrasion.

5. Do I need special ink for UV printers?

Yes, UV printers require UV-curable inks specifically designed to harden under UV light during the printing process.