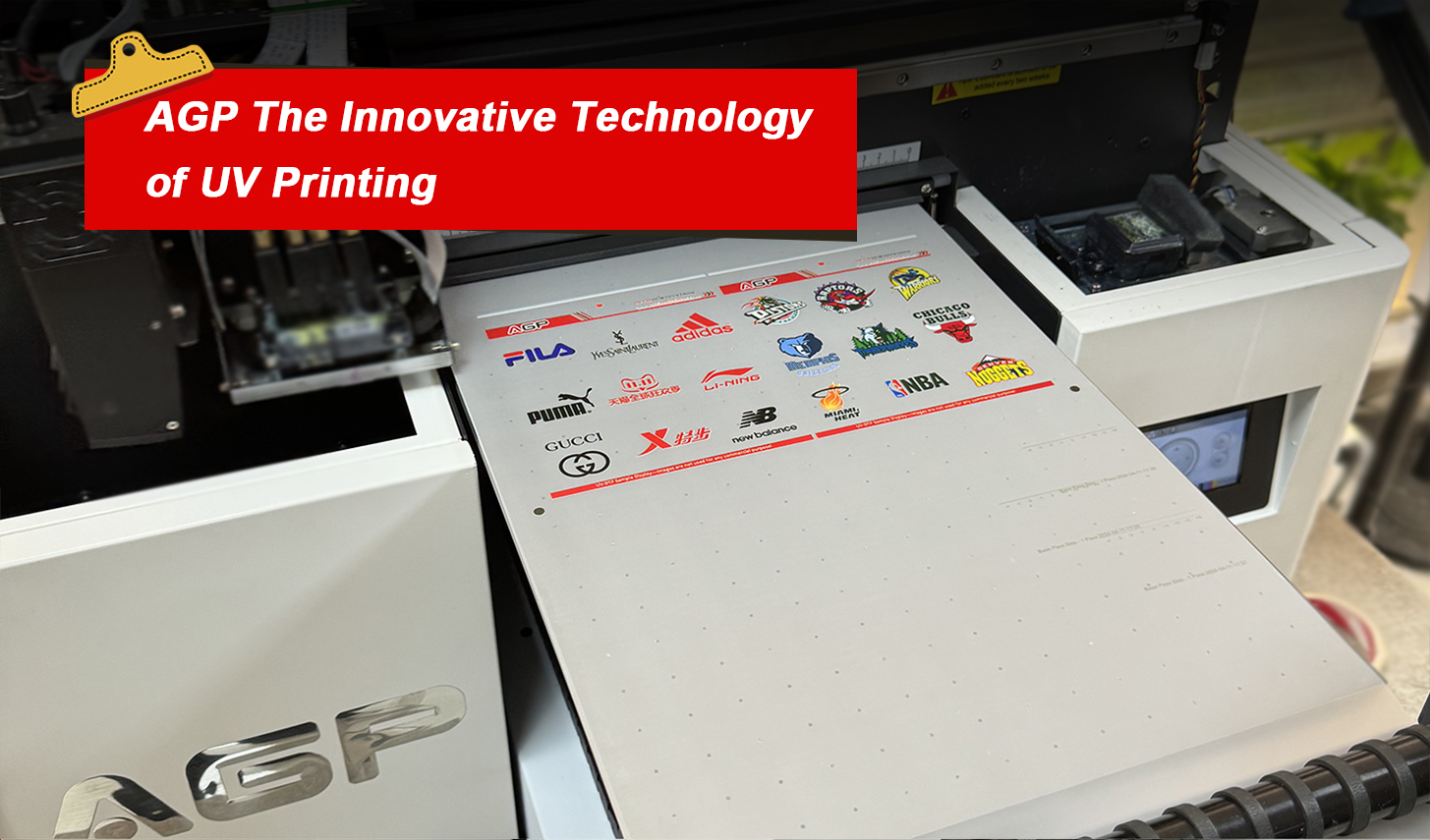

High Precision and Wide Application: The Innovative Technology of UV Printing

In daily life, UV printed products are everywhere. From office supplies to exquisite home decorations, from giant billboards to mobile phone cases and nail art, they decorate our lives with diverse designs and rich colors.

So, what kind of high-tech is UV printing? How does it achieve high-quality digital printing? AGP will analyze it in depth and appreciate the charm of UV printing together.

What is UV Printing?

UV printing is a digital printing technology that uses ultraviolet (UV) curing to directly print and instantly dry UV ink on surfaces. It can achieve high-quality, durable printing on almost all types of materials.

The UV Printing Process

1.Preparation: The image to be printed is designed and edited using graphic software, and converted into a suitable format, and UV printer parameters are set based on printing requirements.

2.Printing Process: The product is placed on the printer’s platform (ensuring the surface is clean and smooth), and the printhead precisely sprays UV ink onto the product’s surface to replicate the design.

3.Curing Process: Unlike traditional printing methods that require baking or air drying, UV printing uses UV lamps for curing. The UV LED lights instantly dry the ink, saving on extra equipment and labor costs while improving production efficiency.

Ultra-high precision of UV printing

UV printing can be precisely controlled at the millimeter level to achieve extremely high printing resolution.

The tiny nozzles in the print head can accurately control the volume and ejection trajectory of the ink droplets and use very little ink to carefully depict the substrate. The ink droplets are evenly distributed on the surface of the material, and after being quickly cured by the UV lamp, a clear and sharp character outline is formed, avoiding blurring or smudges.

This high-precision printing technology has brought innovation and convenience to many industries.

In the field of electronic equipment manufacturing, UV printers can easily print important information such as model and batch on tiny components such as mobile phone motherboards and chips to ensure the accuracy of information transmission;

In the handicraft decoration industry, fine and complex tag logo patterns can be printed to add a sense of refinement and professionalism;

In pharmaceutical packaging, the clear and small-print printing of key information such as drug name, specifications, and production date not only meets regulatory requirements but also improves the neatness and beauty of the packaging.

Advantages of UV Printing

Wide Applicability: Supports printing on a variety of materials such as PET, PVC, metal, acrylic, stone, wood, glass, leather, and more.

Durability: After curing, the ink is resistant to scratching, water, and UV rays, ensuring the print stays vibrant even in outdoor environments.

Eco-Friendly: Uses environmentally friendly ink, reducing pollution, and the quick curing process helps conserve energy, aligning with modern sustainability practices.

Excellent Color and Resolution: Achieves vibrant colors and fine resolution, offering endless possibilities for creative designs.

The Wide Applications of UV Printing

UV printing is widely applied across various fields. With continuous technological advancements and growing market demand, UV printing has become an essential technology in the modern printing industry. Here are some common UV printing applications:

Promotional Products: Customized keychains, brand bottles, and other promotional items are ideal for brand promotion.

Packaging Materials: Display unique and exquisite designs on product packaging to enhance market competitiveness.

Signage and Directional Signs: Create colorful and durable indoor and outdoor signs to meet diverse needs.

Custom Gifts: Such as phone cases, toys, and decorations, enabling personalized designs to cater to consumer preferences.

The Secret to Quality UV Prints

Select the Right Equipment: Choose the right UV printer based on your business needs, such as UV crystal label printers, flatbed printers, or multifunction flatbed printers. AGP offers all these models—please feel free to contact us for detailed information.

Quality Ink: Use high-quality UV inks to ensure vivid colors and high resolution, while extending the lifespan of printheads.

Regular Maintenance: Regular cleaning and maintenance help ensure print quality, prevent machine malfunctions, and extend the life of the printer.

Conclusion

UV plastic printing, with its unique advantages and wide range of applications, shows great potential in fields such as creative product customization, packaging, signage, and electronics. For businesses and individuals seeking to expand their operations or invest in new opportunities, this is undoubtedly a field worth exploring.

Feel free to contact us for more detailed information and professional advice on UV printing. Let’s work together to create a brighter future!