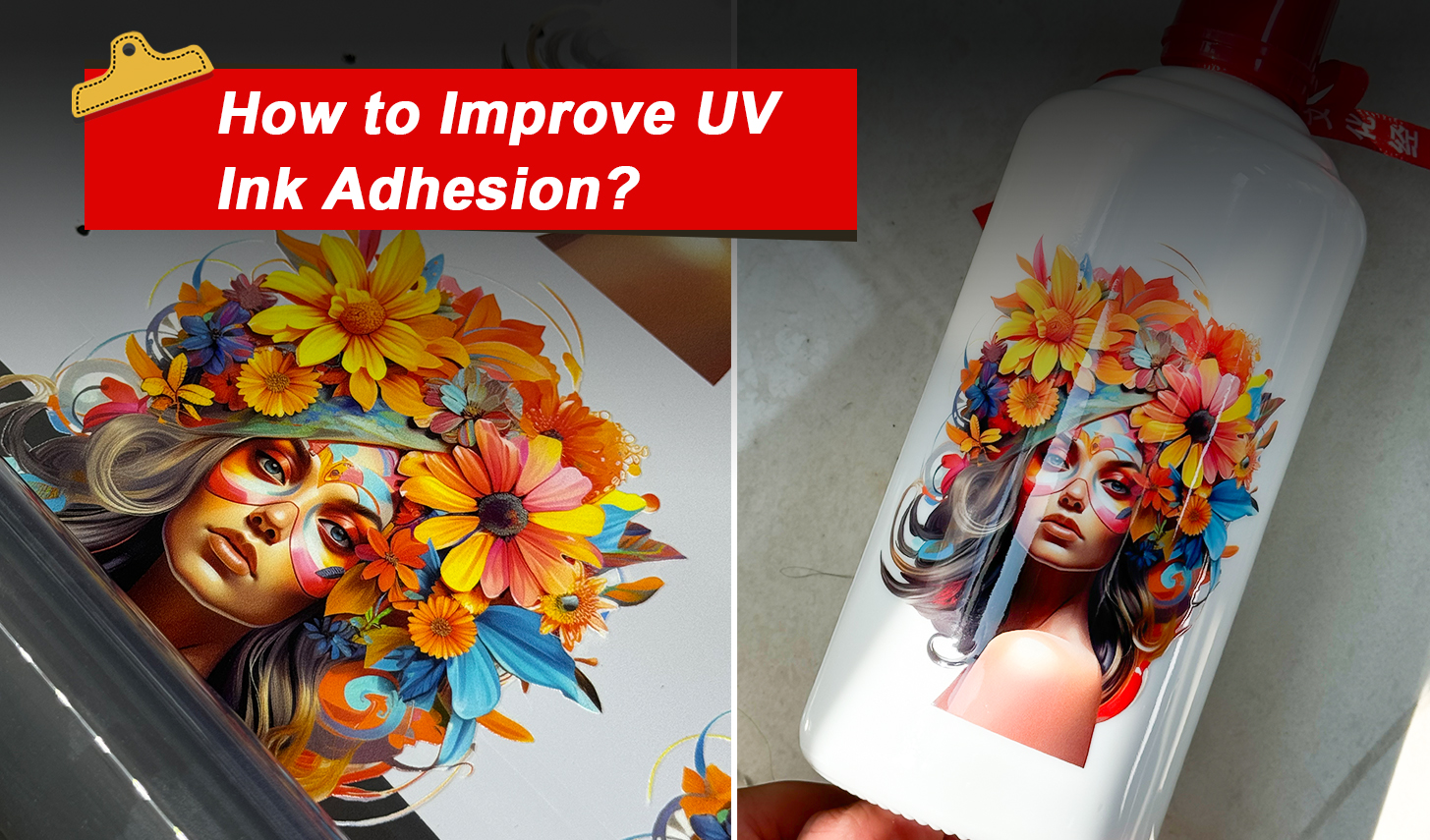

How to Improve UV Ink Adhesion?

We always try to get the prints in their expected colors and precision. Do you think how can you improve the UV ink adhesion? It involves various factors including printer, material, ink, adhesive agent, printer settings, and much more. However, ink adhesion is the most challenging task. It gets more complex when it comes to difficult materials.

Here you will learn all the required details about improving UV ink adhesion. Followed by the importance of choosing a suitable surface (or substrate), and the role of pretreatment.

Factors Affecting UV Ink Adhesion

To improve the stickiness of UV ink, you must first understand what factors influence it. Here are the significant factors:

Substrate Material

The type of material you print on influences how well the ink adheres. Surface textures vary among materials such as plastics, metals, and paper. For example, sleek polymers and metals may not hold ink or rougher surfaces like paper. Knowing how your material reacts to UV ink allows you to make the appropriate modifications.

For instance, compare a textured plastic surface with a smooth one to understand the difference in adherence.

Surface Energy

Surface energy measures how a material's surface bonds to ink. Materials with low surface energy, such as some plastics, reject ink. Pre-treatment can increase the surface energy, allowing the ink to stick better.

Polyethylene and polypropylene are common plastics with low surface energy; corona or flame treatment can help improve ink adhesion.

Ink Composition

The composition of the UV ink also influences adherence. Some inks may be too thick or dry too quickly, making them difficult to stick to the surface. Finding the appropriate balance in the ink's formulation makes it stick to the surface.

Surface Pre-treatment Methods

If you are looking for a nice finishing of prints, you must consider the pre-treatment methods. The primary goal is to prepare the surface for prints. There are multiple techniques, let's discuss them in detail.

Corona Treatment

Corona treatment is a specific procedure that emits high-voltage electric discharge. Once done, it boosts the base energy of the material. It makes the surface more "wettable," allowing the ink to stick better.

A typical application is for plastic film materials in packaging where corona treatment improves the printability of the surface.

Plasma Treatment

This treatment involves the alteration of the material’s base. It uses a specific gas for the procedure leading to stronger UV ink adherence. It is highly required in complex or textured materials to get even results. This treatment works smartly on glass and ceramic material

Chemical Priming

Chemical priming involves the application of a specific chemical before printing to aid ink adhesion. This primer strengthens the bond tightly between the ink and the material. It works to boost adherence. However, it is important to choose a primer that is highly compatible with your material and the ink.

How to Improve UV Ink Adhesion?

UV ink adhesion is followed by a complete process. Let us discuss the process in detail to improve UV ink adhesion with smart suggestions.

.png)

Adjust Print Settings

No doubt inks play an important role in adherence, printer settings are essential too. In UV printers, the strength and time for light exposure must be appropriate. If the ink is cured properly under UV, it ensures effective adherence.

You can run a test print at different UV lamp intensities to find the ideal exposure time for your specific surface.

Important: If you are confused in a printer, AGP UV printers are ideal for users who are looking for simpler processes.

Maintain Your Equipment

Keeping your printing equipment clean and in good working order is critical. Dirty or worn-out elements, such as rollers and print heads, impact ink application and adherence. You can perform regular maintenance to avoid these complexes

However, a scheduled cleaning for print heads can reduce the ink spreading issues. You can fix it weekly or bi-weekly according to your usage.

Test and Evaluate

Finally, you can test and then evaluate your printing process. It saves from all possible hazards. You can test before proceeding on a large batch. Testing different materials and various inks can help you design your required combination. You can also check the print quality often, so you can resolve the issues beforehand. Importantly, record every test results and findings of your combination. It helps to improve the printing process easily.

Ink Selection and Optimization

Are you wondering why ink selection is an important factor to consider? While choosing the correct ink, it is important to select and choose the ink that is suitable for your printer and material. It will help you to increase the chances of good adhesion.

.png)

Choose High-Quality UV Inks

When you are looking for UV ink, the first thing to consider is your material. The ink must be compatible with your fabric. Different materials behave differently with the same inks. High-quality inks ensure strong adhesion, consistent colors, and long-lasting prints. Low-quality inks not only disturb the print's quality, it affect the printers badly.

You can check for AGP UV ink which has proven results. It ensures the print quality and makes them look appealing. You will experience perfect viscosity to blend the colors naturally.

Adjust Ink Viscosity

Ink viscosity is the thickness of the ink. This thickness determines how it will stick to your fabric. The consistency of ink must be normal not thick or thin. It will lead to strong adhesion within the prints.

It is better to select ink that is reliable to be used on your printer and fabric. You need to adjust the viscosity according to the temperature. Warm temperatures do require thick inks to avoid spread.

Consider Ink Additives

Ink additives are the sticking materials that are used to stick the design to the substrate. The purpose of using these additives is to promote adherence. You can use these inks to cope with complex or textured materials. You can try different formulations to get the optimum solution for your printing requirements.

Conclusion

To get the UV prints on point, you need to focus on the improvement of adhesion. It is accomplished by following a proper technique. You need to consider good quality material and coordinating ink. By choosing AGP’s UV ink you will be able to achieve high-quality prints with strong durability. Having a reliable printing technique can resolve complex issues like prints on textured materials. Furthermore, it is essential to perform regular testing. It helps in running the printing projects efficiently.