How to optimize the cost and efficiency of UV DTF printing?

Companies in the printing industry are seeking cost-effective and efficient processes. UV DTF (direct to film) printing is a solution that enhances printing processes. It provides vivid colors and high-quality printing effects. Optimizing the cost and efficiency of UV DTF printing requires careful consideration of various factors. In this blog post, we’ll explore some key strategies to help you get the most out of your UV DTF printing operations.

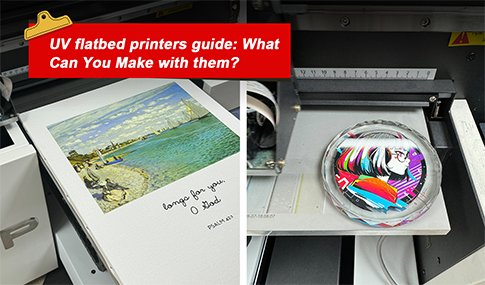

Invest in High-Quality Equipment

To optimize UV DTF printing, invest in high-quality equipment, including UV printers, film materials, curing units, and other accessories. Although the initial investment may appear intimidating, investing in high-quality equipment will yield superior results, reduce downtime due to malfunctions, and ultimately lower long-term costs.It is recommended that you choose AGP UV DTF printer for efficient printing and guaranteed after-sales service.

Choose the right movie

Choosing the right film material is critical to successful UV DTF printing. Choose a high-quality film that is compatible with UV inks and has excellent adhesion to the substrate. Conduct thorough testing to determine which film is best for your specific printing needs. Considering factors such as durability, flexibility and print quality, the best choice is undoubtedly AGP UV Film, which can be matched with our UV printers for maximum efficiency.

Optimize Ink Usage

Optimize ink usage by adjusting print settings such as ink density, resolution, and curing time to achieve optimal results while using the least amount of ink possible. Consider using ink-saving techniques such as nesting and gang printing to maximize efficiency.

Streamline Workflow

Maximize the efficiency of UV DTF printing by implementing automated processes wherever possible, such as job scheduling, file preparation, and print queuing. Ensure staff are trained in efficient workflow management. Maximize the efficiency of UV DTF printing by implementing automated processes wherever possible, such as job scheduling, file preparation, and print queuing.

Train Staff

Invest in workflow management software that integrates seamlessly with your printing equipment and streamlines the entire production process from start to finish. Proper training is crucial to ensure that your printing staff can operate equipment effectively and troubleshoot any issues that arise. Comprehensive training programs should cover equipment operation, maintenance procedures, and best practices for UV DTF printing. Well-trained staff can minimize costly errors and downtime, ultimately improving overall efficiency.

Implement Quality Control Measures

Implementing quality control measures is crucial in UV DTF printing to ensure consistent, high-quality results. It is important to establish rigorous quality control measures at every stage of the printing process, from file preparation to final inspection. Regularly calibrate equipment, monitor print output for defects, and implement corrective actions as needed to maintain quality standards and minimize rework.

Explore Material Cost Reductions

Additionally, exploring material cost reductions can help to improve overall efficiency and profitability. Consider exploring opportunities to reduce material costs when optimizing printing processes. This can be achieved by negotiating bulk discounts with suppliers, seeking alternative sources for film materials, or switching to more cost-effective substrates without compromising print quality. Even small reductions in material costs can add up to significant savings over time.

Monitor and Analyze Performance

Remember to monitor and analyze performance. To identify areas of improvement and optimize UV DTF printing processes, it is essential to continuously monitor and analyze key performance metrics. Metrics to track include ink consumption, material usage, production throughput, and downtime. By tracking these metrics, inefficiencies can be identified, and targeted improvements can be implemented.

In conclusion, to optimize the cost and efficiency of UV DTF printing, businesses should take a holistic approach that includes equipment, materials, workflow, staff training, quality control, and performance monitoring. By implementing the strategies outlined in this blog post, businesses can maximize their return on investment in UV DTF printing technology and deliver superior results to their customers.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Welcome to AGP! With nearly a decade in the printer industry, we specialize in R&D and manufacturing, offering exclusive DTF and UV DTF printer solutions. With a worldwide footprint, including partnerships with distributors in the USA, Canada, UK, Italy, and Spain, let's unite to advance into the next stage of business expansion!

Drop us an email and let’s make great things happen: info@agoodprinter.com

Contact us through WhatsApp and let's talk furthermore: +86 17740405829