How to Print in White Ink: Techniques, Printers & Best Practices Explained

Traditionally, white inks are opaque. They work perfectly to give versatile prints without using silkscreen or foils. In the old days, reverse printing was used to print the dark around the blank fonts, which was the only way to achieve the white effect on print. It could be mixed with other colors to give a natural hue with amazing colors.

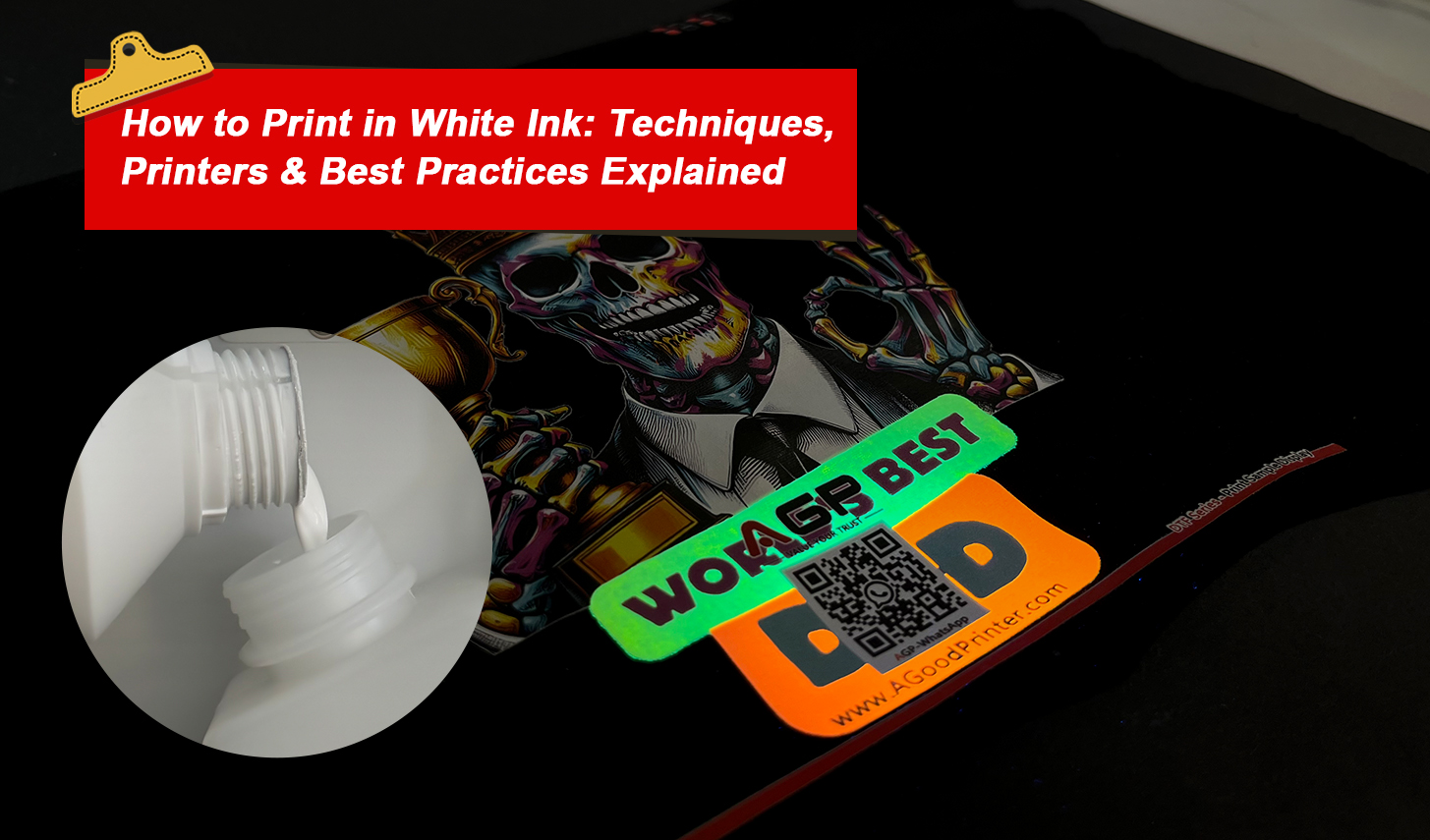

Modern printers can print with white Ink, which gives value to dark paper with multiple runs. It makes the print highly bold and unique for the target. This article will cover all the details about how to print in white ink and the quality required to produce the expected prints. In the meantime, you will learn the qualities of white inks and how they work.

Introduction to White Ink Printing

White ink printing is a technique that produces prints on different surfaces using white Ink. It uses various materials, such as dark or mixed-colored materials. Typically, white prints do not include colors; they are formulated with special Ink that specializes in producing vibrant and opaque prints.

There are multiple advantages of using white ink printing, including:

- It brings out the details

- Pop up the design on darker substrates.

- Add the depth to the artwork.

- It gives a unique and fantastic effect.

White ink printing is equally effective on vinyl, acrylic, metal, glass, and wood.

It could be used in various projects, such as signage, promotional items, or personalized products. White Ink gives your substrate an appealing allure.

Types of Printers That Support White Ink

White Ink is not convenient for traditional printers. Modern printing techniques can deal with white colors for vibrant and excellent results. However, choosing one printing technique for your printings depends upon your needs, budget, the volume of prints, and most importantly, the material. A few printing techniques that allow white ink printing are:

White ink UV printing

UV printing is a modern yet beneficial printing technique. It uses a specialized machine that gives instant drying when reacted with UV light. It provides sharp, vibrant, and opaque prints.

White ink screen printing

Screen printing could be used for white ink printing. This technique requires two silk screens perfectly lodged, which works for applying prints. However, it is only suitable for larger images. Further, it is only recommended in shorter runs because it gets expensive when working with a larger number.

White Ink DTF printing

DTF printing technique uses special kind of inks that makes the prints on various fabrics. Our best DTF printers are equipped with versatile DTF white inks that give long-lasting and appealing prints. It is especially recommended on fabric printing.

How to Print in White Ink?

White inks are very popular in commercial printing and packaging. They are considered a good choice where maintaining color vibrancy, improved readability of texts, and multiple design options are required. Follow the process of printing in white Ink. Ultimately, you will be able to create designs that will stand out.

Step 1: Look for the Requirement of White Ink

The first step of every process is planning. You need to see whether your design requires white Ink. This is necessary when you are required to make suitable, opaque designs.

Step 2: Select a Printing Technique

Multiple printing techniques, such as white Ink, can be used to make your prints. These methods include UV printing, screen printing, and others. Every methodology has pros and cons; you must consider each aspect before selecting one. UV printing is excellent and suitable for large volumes, whereas screen printing is suitable for a limited number of prints.

Step 3: Choose the Correct Substrate

Substrate plays a vital role in every printing. Select the substrate according to your printing technique, budget, and Ink. You must choose the only option compatible with white Ink for this specific printing.

Step 4: Prepare Your Design

Once you know the substrate, design requirements for white Ink, and the methodology, it's time to make the design. Make a proper design, and don't forget to add a separate layer of white Ink. You may need a separate printing plate or Ink for white Ink.

Step 5: Print and Test

Before you start printing in bulk, it's better to test the print quality by running a print test. In this step, you will print a short amount of your design and see how it looks with white Ink. You can check the amount of white Ink in your design. Once the design seems promising, you can move to the final step.

Step 6: Print Your Design

Now that everything is designed correctly, it’s time to make the prints. You can use the information gathered from the testing phase to adjust the printer's settings. It is essential to note the amount of Ink, substrate, and printing method used here; the drying time may vary. Once dried, it’s ready for trimming and finishing.

Step 7: Review the Final Product

When everything is done, it's time to review your prints. You must see whether the final result meets your expectations. You can make adjustments based on the feedback you will gather after review.

Pros and Cons of White Ink Printing

There are multiple pros of using white ink printing and some cons of using these inks, too.

Pros

The pros of white ink printing include the following:

- More Vibrant prints than traditional ones

- Gives high contrast results

- Color rendering is improved

- Multiple substrates are allowed for printing

- Lower the overall cost

- Can make layered dimensions

Cons

Some of the cons of using white ink printing are:

- High cost is consumed on toners

- It could only be used as a single-layer

- White ink printing limited applications

- It's complex to take care of white inks

- It only gives vibrant prints on dark papers

- Requires tight cleaning

Reasons to Use a White Ink Printer

White ink print, besides its opaque nature, has numerous other reasons to be used, including:

Produces More Vibrant Colors

During printing with white inks, colors pop out and shine. As a result, you get highly appealing prints that can increase your business's reach and leverage your growth.

Enables Prints on Various Surfaces

A white ink printer usually allows you to make prints on multiple surfaces. It can be used on various colored materials, including paper. However, white substrates are not likely to appear.

Conclusion

Although it could be a challenge for people to add the additional cost of white inks, the amazing results of white ink prints on dark objects give an appealing allure. They enhance the background by applying layers of white Ink. The ink quality should not be compromised to have opaque and fine-finishing prints. Modern printers, including UV and DTF printers, can print with white ink. Moreover, the process is quick and satisfactory.

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Welcome to AGP! With nearly a decade of experience in the printer industry, we specialize in R&D and manufacturing, offering exclusive DTF and UV DTF printer solutions. With a global presence, including partnerships in the USA, Canada, UK, Italy, and Spain, we’re ready to take the next step in business expansion together!

Contact Us:

Email: info@agoodprinter.com

WhatsApp: +86 17740405829