How UV Flatbed Printers Print on Irregular Surfaces?

UV flatbed printers have revolutionized the digital printing world by offering versatility, speed, and high-quality results. This technology allows businesses to print on various materials, from glass to metal, making it suitable for advertising, packaging, and product customization industries. In this article, we’ll explore how CCD scanning technology enhances print precision, the ability to print on irregular surfaces, and how integrating UV printing with 3D technology is opening up new creative possibilities.

What is UV Flatbed Printing?

UV flatbed printing is a digital printing process where UV light is used to cure the ink as it’s applied instantly. This immediate curing process eliminates the need for drying time, speeding up production. The key advantage of UV printing lies in its ability to print on a wide range of materials, including plastic, wood, glass, and metal. It’s ideal for applications requiring vibrant, durable prints, such as outdoor signage, promotional items, and custom products.

With UV printing, you can expect sharp, detailed prints that are resistant to the elements, ensuring longevity even in harsh conditions.

How to Print on Irregularly Shaped Objects: A Simple Guide

Printing on irregularly shaped surfaces can be challenging, but UV printing offers a solution with high-quality results. Here’s how to successfully print on non-flat objects:

-

Choose the Right Printer: Opt for a UV flatbed printer that supports printing on uneven surfaces. The AGP UV6090, for example, can handle a variety of shapes and sizes, making it perfect for this task.

-

Prepare the Object: Clean the surface thoroughly to remove any dust, grease, or oils. A clean, smooth surface ensures proper ink adhesion. Test fit the object on the printer bed and make adjustments if necessary.

-

Adjust Printer Settings: Set the resolution and print mode according to the material and shape of the object. Larger objects may require a lower resolution for faster printing, while smaller items need higher resolution for detailed designs.

-

Secure the Object: Position the object securely on the print bed. Use clamps, foam pads, or custom holders to stabilize the item. This step is critical to ensure the printhead aligns properly with the surface.

-

Monitor the Printing Process: Begin printing while monitoring the alignment and quality. UV printers use instant curing, which reduces smudging, even on irregular surfaces.

-

Post-Print Curing (If Needed): For objects with complex shapes, extra curing might be needed. Some UV printers come with built-in curing lamps, but an external UV curing station may be necessary for uneven surfaces.

-

Final Inspection and Touch-ups: After curing, inspect the print for any defects. Touch up any areas that may need additional layers of ink to ensure the final result meets the desired quality.

Enhancing Precision with CCD Scanning Technology

One of the standout advancements in UV flatbed printing is the integration of CCD (Charge-Coupled Device) scanning technology. The AGP UV6090, for instance, uses CCD scanning to improve print alignment and ensure precise, high-quality results.

CCD scanning automatically corrects the printhead’s alignment, reducing human error and increasing efficiency. This technology is particularly useful for intricate designs and multi-layer prints, making it ideal for industries such as custom packaging, signage, and fine art reproduction.

By ensuring perfect color registration, even in complex prints, CCD scanning boosts both the quality and productivity of UV printing, allowing for consistent results from start to finish.

Overcoming Irregular Surface Challenges

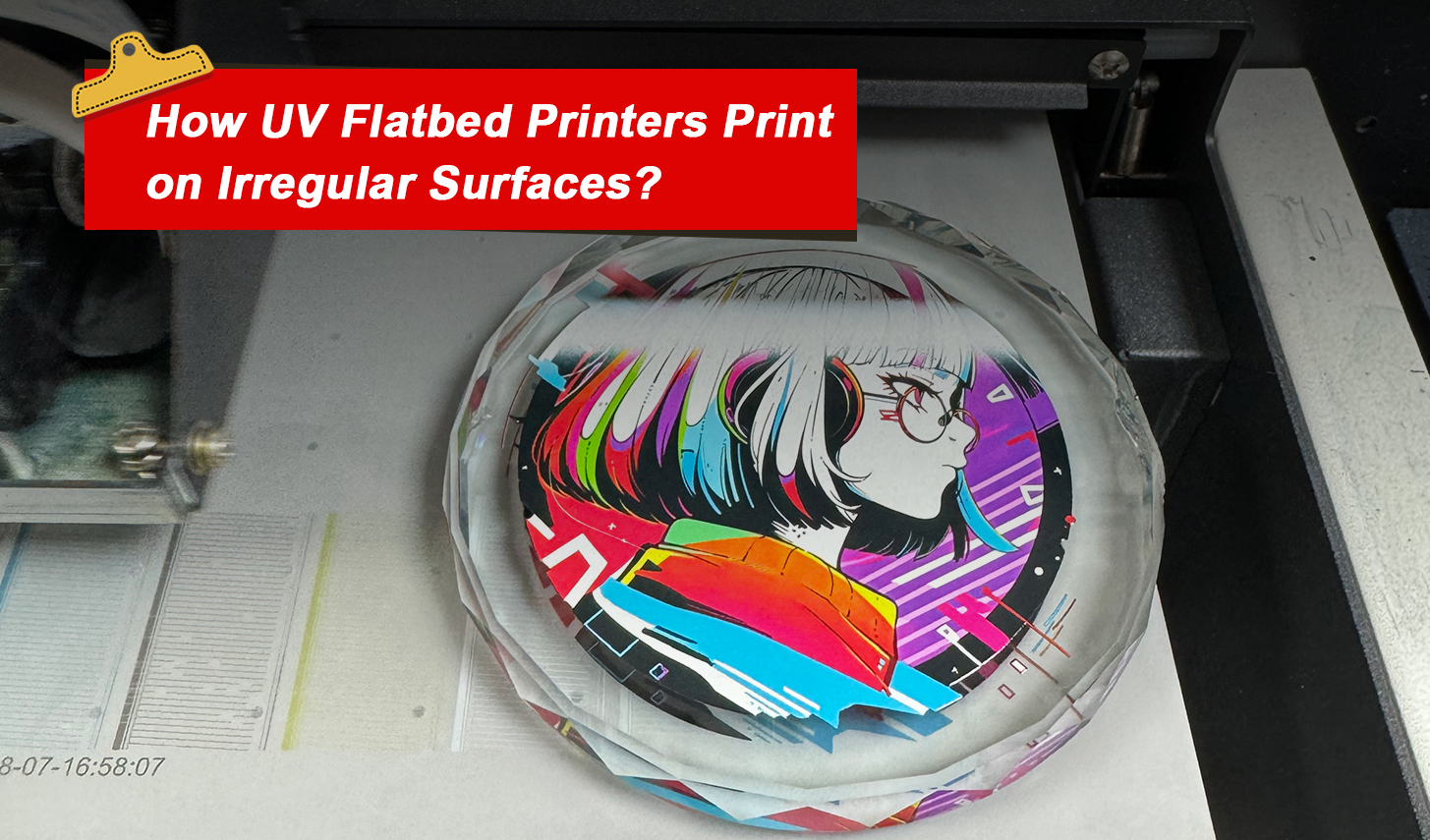

Traditional printing methods often struggle with irregular surfaces, but UV flatbed printers excel in this area. These printers can print on curved, textured, or multi-dimensional objects with exceptional accuracy, maintaining the integrity of the design.

Whether printing on custom smartphone cases, 3D objects, or curved items like water bottles, UV printers can deliver high-quality, detailed designs without distortion. The ability to print directly onto non-flat surfaces opens up new possibilities for product customization and innovation.

Modern UV printers can adjust for surface irregularities, ensuring consistent print quality across diverse materials. This makes UV printing ideal for businesses looking to offer more creative, personalized products.

The Integration of 3D Printing and UV Flatbed Printing

Combining UV printing with 3D printing offers exciting new creative possibilities. With 3D printing, manufacturers can create raised surfaces or textured patterns on objects, which can then be enhanced with vibrant UV prints.

This combination of technologies is particularly beneficial for industries that rely on high-impact visuals and tactile experiences, such as custom gifts, luxury packaging, and high-end signage. The ability to combine 3D textures with vibrant UV colors provides endless opportunities for product innovation and customization.

For instance, a 3D-printed object can be enhanced with detailed UV prints that showcase complex designs, textures, and color gradients, resulting in unique and striking products that stand out in the market.

How to Choose the Best UV Flatbed Printer

When selecting a UV flatbed printer, it’s essential to consider several factors to ensure it meets your specific needs:

-

Print Area and Material Thickness: Make sure the printer’s print bed is large enough to accommodate your objects. For example, the AGP UV6090 offers a print area of 600x900mm and can handle materials up to 160mm thick, making it suitable for large or bulky items.

-

Print Resolution: High resolution is crucial for detailed designs. The UV6090 supports resolutions up to 3600 DPI, making it ideal for intricate artwork and high-quality prints.

-

Automation Features: Look for printers with automation features like CCD scanning and automatic printhead alignment. These technologies improve efficiency and reduce the risk of errors, especially for large print runs.

-

Software Compatibility: Ensure the printer is compatible with industry-standard RIP software like Maintop or FlexiPRINT, which can help optimize color management and streamline the printing process.

The Future of UV Printing: Emerging Trends

The future of UV printing is bright, with continued advancements expected in areas like speed, efficiency, and precision. LED UV curing technology is already making waves by reducing energy consumption and speeding up curing times. Furthermore, improvements in printhead technology and software will enhance printing capabilities, making the process even faster and more cost-effective.

In the coming years, AI and machine learning will likely play a larger role in the printing industry, enabling printers to optimize print quality in real time. As 3D and UV printing technologies converge, businesses can expect even more innovative solutions for product customization and packaging.

Conclusion

UV flatbed printing technology offers unmatched versatility, precision, and speed, making it an indispensable tool for businesses across various industries. Incorporating CCD scanning technology and integrating 3D printing capabilities have elevated UV printing to new heights, enabling businesses to produce high-quality, customizable products on a wide range of materials.

With printers like the AGP UV6090, which offers high resolution, large print areas, and advanced automation features, businesses can push the boundaries of creativity and innovation. Whether you’re printing on irregular surfaces, combining UV and 3D printing, or creating intricate designs, UV flatbed printing is the solution you need to take your printing capabilities to the next level.

If you're looking for a reliable and high-performance UV flatbed printer, the AGP UV6090 provides the perfect solution, helping you meet the demands of modern printing applications with ease.