Blog

-

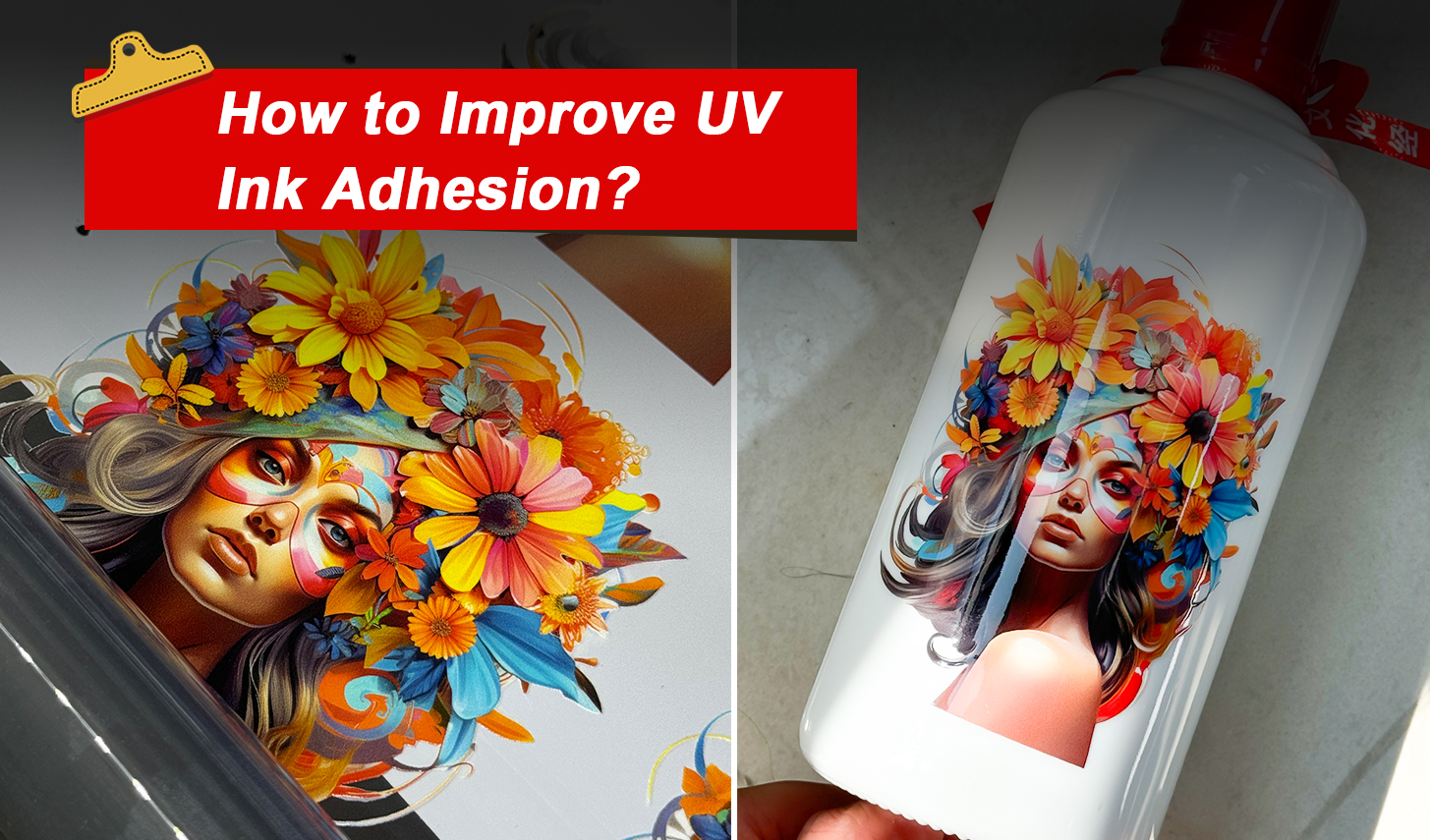

How to Improve UV Ink Adhesion?Do you want to improve the adherence of UV ink? In this article you will learn more about ink choices, surface treatments, and other ways to produce long-lasting and excellent prints.Learn More2024-09-12

How to Improve UV Ink Adhesion?Do you want to improve the adherence of UV ink? In this article you will learn more about ink choices, surface treatments, and other ways to produce long-lasting and excellent prints.Learn More2024-09-12 -

Can DTF Heat Transfer be Done with an Iron?The DTF heat transfer process has revolutionized the textile decoration industry. Especially in the apparel industry, it can bring fine and rich patterns, true colors and high-quality prints to the products. However, with the popularity of DTF technology, some misconceptions have emerged.Learn More2024-09-06

Can DTF Heat Transfer be Done with an Iron?The DTF heat transfer process has revolutionized the textile decoration industry. Especially in the apparel industry, it can bring fine and rich patterns, true colors and high-quality prints to the products. However, with the popularity of DTF technology, some misconceptions have emerged.Learn More2024-09-06 -

A Comprehensive Analysis of UV Printer Market Forecast and TrendsAre you still wondering about UV Printer Market Forecast and Trends? Find the latest trends in its growth with real-time facts and figures. You will see the overview, key drivers, and segments of UV printers.Learn More2024-09-05

A Comprehensive Analysis of UV Printer Market Forecast and TrendsAre you still wondering about UV Printer Market Forecast and Trends? Find the latest trends in its growth with real-time facts and figures. You will see the overview, key drivers, and segments of UV printers.Learn More2024-09-05 -

Latex vs UV Printing – The Best Option for Your NeedsLatex and UV Printing – Which Is the Best Option for My Needs? We explore the differences as well as the advantages of both printing formats. This will help you make an informed decision that will deliver the results you want.Learn More2024-08-30

Latex vs UV Printing – The Best Option for Your NeedsLatex and UV Printing – Which Is the Best Option for My Needs? We explore the differences as well as the advantages of both printing formats. This will help you make an informed decision that will deliver the results you want.Learn More2024-08-30 -

How to Clean a Printhead with No Fuss?You'll agree when I say it's highly frustrating when you're in the middle of an urgent printing project, and the printer starts acting up. Suddenly, it produces faded prints with ugly streaks across them.

How to Clean a Printhead with No Fuss?You'll agree when I say it's highly frustrating when you're in the middle of an urgent printing project, and the printer starts acting up. Suddenly, it produces faded prints with ugly streaks across them.

If you are in the business of producing quality prints, this situation is unacceptable. Since the poor quality printing is probably due to a clogged printer head, keeping your printer's printhead in top condition is vital for business.

One way to do this is to clean it frequently. Cleaning printheads regularly prevents them from clogging up and spoiling your prints. Regular cleaning also preserves the condition of your printer, ensuring that it will continue producing quality prints that customers demand.Learn More2024-08-21 -

UV DTF Stickers and Self-Adhesive Stickers: Which one do you prefer?Self-adhesive stickers, a veteran star in the advertising industry, are ubiquitous in daily life thanks to their affordability, flexibility, and wide range of applications. In recent years, UV DTF films have gained popularity at industry trade shows, but what exactly sets UV DTF Films apart from traditional Self-Adhesive Stickers? Which one should you choose?Learn More2024-08-16

UV DTF Stickers and Self-Adhesive Stickers: Which one do you prefer?Self-adhesive stickers, a veteran star in the advertising industry, are ubiquitous in daily life thanks to their affordability, flexibility, and wide range of applications. In recent years, UV DTF films have gained popularity at industry trade shows, but what exactly sets UV DTF Films apart from traditional Self-Adhesive Stickers? Which one should you choose?Learn More2024-08-16