Blog

-

AGP UV DTF printer Helps Customize Packaging and Empower ProductsTraditional packaging customization has three major difficulties: "high price, difficult implementation, and slow production". This is due to the high threshold of traditional factory packaging customization purchase orders, resulting in high price costs for small and medium-sized orders, and it is difficult to match production.Learn More2023-05-31

AGP UV DTF printer Helps Customize Packaging and Empower ProductsTraditional packaging customization has three major difficulties: "high price, difficult implementation, and slow production". This is due to the high threshold of traditional factory packaging customization purchase orders, resulting in high price costs for small and medium-sized orders, and it is difficult to match production.Learn More2023-05-31 -

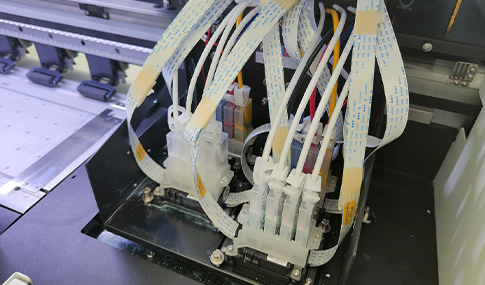

What can we do if the ink cannot output during loading or cleaning?No matter DTF printer, eco-solvent printer or smaller UV flatbed printers, mostly configuration with Epson printhead, like F1080,DX5,I3200 or something else.

What can we do if the ink cannot output during loading or cleaning?No matter DTF printer, eco-solvent printer or smaller UV flatbed printers, mostly configuration with Epson printhead, like F1080,DX5,I3200 or something else.

For our normal use,sometime you may met the problem one or two colors cannot come out,here we have some steps to check:Learn More2023-05-26 -

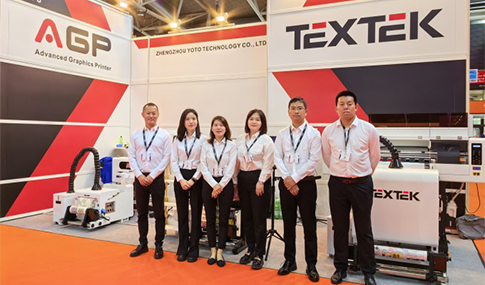

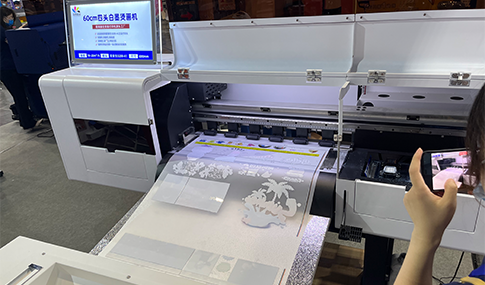

AGP PARTICIPATED IN FESPA GLOBAL PRINT EXPO MUNICH 23-26 MAY 2023At the FESPA Munich exhibition, the AGP booth was filled with energy and excitement! The eye-catching black and red logo of the AGP small-size A3 DTF printer and A3 UV DTF printer attracted numerous visitors. The exhibition showcased a range of AGP products, including the A3 DTF Printer, A3 UV DTF Printer, and their white and exquisite designs won the admiration and recognition of many attendees.Learn More2023-05-24

AGP PARTICIPATED IN FESPA GLOBAL PRINT EXPO MUNICH 23-26 MAY 2023At the FESPA Munich exhibition, the AGP booth was filled with energy and excitement! The eye-catching black and red logo of the AGP small-size A3 DTF printer and A3 UV DTF printer attracted numerous visitors. The exhibition showcased a range of AGP products, including the A3 DTF Printer, A3 UV DTF Printer, and their white and exquisite designs won the admiration and recognition of many attendees.Learn More2023-05-24 -

Maybe sometime you will found that the printed film with some water bubble after stock some days, so what happened?As we know the printer with heating function which can cure 40-50% white ink before the film enter into powder machine. And then you will set up the thermostat temperature to 110~140℃,under this condition the powder will be melt as a primer, then there will be 30~40% water remaining in the white ink (between the PET film and powder primer). The inside water may produce water bubble or blister after condensation.Learn More2023-05-22

Maybe sometime you will found that the printed film with some water bubble after stock some days, so what happened?As we know the printer with heating function which can cure 40-50% white ink before the film enter into powder machine. And then you will set up the thermostat temperature to 110~140℃,under this condition the powder will be melt as a primer, then there will be 30~40% water remaining in the white ink (between the PET film and powder primer). The inside water may produce water bubble or blister after condensation.Learn More2023-05-22 -

Why L1800 DTF printers always occurred errors during working?L1800 printer, is one of the most popular printers that used for modified DTF printer.The main parts like mother board, carriage, print head, gantry and a few other parts still retained,then add the ink supply system like a white ink tank and stirring device. Even someone also add the feeding system which can use roll to roll printing instead of A3 or A4 sheet printing.Learn More2023-05-22

Why L1800 DTF printers always occurred errors during working?L1800 printer, is one of the most popular printers that used for modified DTF printer.The main parts like mother board, carriage, print head, gantry and a few other parts still retained,then add the ink supply system like a white ink tank and stirring device. Even someone also add the feeding system which can use roll to roll printing instead of A3 or A4 sheet printing.Learn More2023-05-22 -

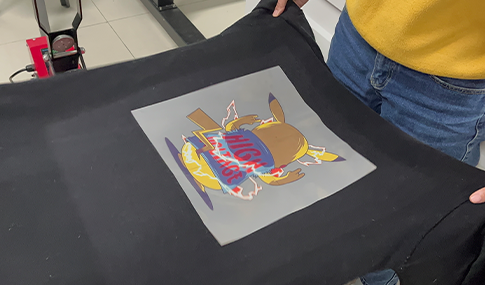

What influences the quality of DTF transfer?As many who have dabbled in DTG printing realize, getting the perfect picture isn't as easy as you might think. If you're considering purchasing or printing your own DTF transfer, let's review the top things to look out for.Learn More2023-05-19

What influences the quality of DTF transfer?As many who have dabbled in DTG printing realize, getting the perfect picture isn't as easy as you might think. If you're considering purchasing or printing your own DTF transfer, let's review the top things to look out for.Learn More2023-05-19