The Ultimate Guide to DTF Printing Powderless Solutions

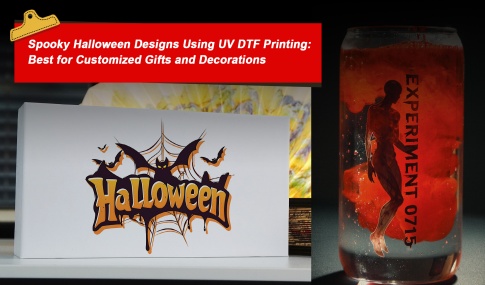

DTF Printing has only been around for about 20 years but has already significantly impacted the entire digital printing industry. Compared with traditional printing technology, it has the advantages of vivid patterns, good durability, high permeability, and can achieve complex designs.

The powderless solution has been innovatively launched with the rapid development of DTF Printing technology. It eliminates the need for hot melt powder in DTF Printing solutions and provides a groundbreaking alternative for textile printing. Do you know this new printing solution? Follow AGP to learn more about it!

1. What is powderless DTF Printing?

Powderless DTF Printing is a new digital printing technology and an upgraded process of traditional DTF printing.

A key step in the traditional DTF printing process is to evenly sprinkle hot melt powder on the pattern to ensure that the pattern can be firmly attached to the fabric's surface. However, this method often results in the printed pattern having a poor feel and low permeability. If the operation is not done properly, the edges of the pattern may have adhesive residue.

To overcome these limitations, the powderless DTF Printing solution came into being. It abandons the use of hot melt powder in the printing process, removes the steps of powdering, shaking, and drying, and instead uses glue to print directly on the PET film.

The emergence of powderless DTF Printing technology marks an important step for DTF printing technology to be more efficient, environmentally friendly, and safer.

2. Printing process of powderless DTF Printing

The powderless DTF Printing process simplifies the operation process and achieves the best effect in three steps: design, printing, and heat transfer. Each step is precise and efficient, showing the charm of modern printing technology.

Step 1. Design the pattern

Design your design on the computer and use graphics software to convert it into the correct image format to ensure successful printing.

Step 2. Powderless printing

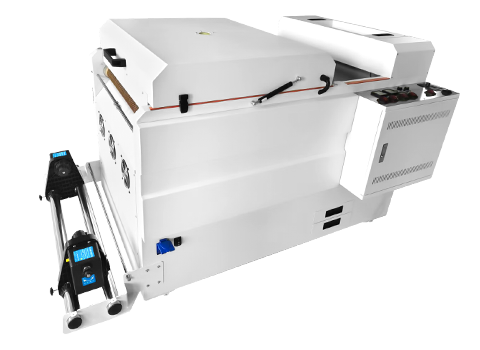

Use a powderless DTF printer to print the pattern directly onto the PET film.

PS: In this step, the powder sprinkling and shaking process are replaced, and the powderless solution is to print the glue directly on the PET heat transfer film as a special adhesive.

Step 3. Heat transfer

The finished PET film is placed on the fabric to be transferred, and the heat press is set to the required pressure and temperature. After the machine stops working, peel off the PET film, and the pattern is transferred to the fabric.

3. Common heat transfer & Powderlessheat transfer Process Comparison

| Process | common heat transfer | Powderless heat transfer |

| Required Equipment | DTF Printer, powder shaker, purifier, heat press machine | DTF Printer, drying equipment, heat press machine |

| Color performance | Color performance is sometimes poor | Great color performance at all times |

| waterproof | Level 4-5 | Level 4-5 |

| Permeability | Not good enough | Good |

Thickness of film |

With some thickness |

Almost no thickness, tight to the surface of the medium |

| Feeling | Glue feeling | Soft and comfortable |

| Durability | Washing degrees 3-4 | Avoid vigorous rubbing and repeated washing |

Through the above comparative analysis, the AGP powderless solution is indeed worth the expectation.

4. Advantages of the powderless DTF Printing solution:

No glue feeling, delicate and more permeable, improving comfort and texture;

1. Save production process, save labor costs, and improve operation efficiency;

3. No need to purchase hot melt powder, powder shaking machine, and purifier, saving purchase costs;

4. Save DTF ink costs, the powderless DTF Printing solution can directly use color ink to print white substrates, greatly saving ink costs. In addition, using white ink to print dark fabrics will have brighter effects.

5. It avoids the smoke emission and noise pollution of common DTF printing and can create a quieter and safer working environment for enterprises.

5. Disadvantages of the PowderlessDTF Printing Solution

1. Strict standards for consumables

The powderless printing solution has high requirements for the quality of glue. If poor-quality glue is used instead of hot melt powder, it may lead to poor printing and transfer effects, affecting the final printing effect.

2. Lower washing fastness

Compared with traditional DTF printing solutions, the washing fastness of the powderless DTF printing solution is a little insufficient, which may affect the durability and service life of the product.

6. Limited areas of application

As powderless DTF printing technology is still under development, there are still some technical challenges and problems to overcome. This technology is not suitable for all types of fabrics.

Conclusion

Every printing solution has its advantages and disadvantages. Customers can choose the printing process that suits them according to the characteristics of the fabric, the purpose, cost, and other aspects.

However, it is undeniable that the powderless DTF printing solution represents a major advancement in the field of DTF printing-- excellent printing effect and a more environmentally friendly solution. It saves time and effort for corporate production and creates an industrial-grade high-efficiency experience!

If you have any questions about the DTF printing process, please contact AGP, we will provide you with professional technical guidance and equipment support.