UV Printing vs. Pad Printing: Which is Better?

UV Printing vs. Pad Printing: Which is Better?

Many people wonder what the difference is between pad printing and UV printing, and which is better. Today I will take you through these two different printing processes. Please continue reading, I believe you will have the answer in your mind after reading this article!

What is UV printing?

UV printing is a printing method that uses UV light to dry ink almost immediately after printing it onto an object. UV printing can be done on a variety of materials, including leather and paper. When UV ink is printed onto an object, the UV light inside the printer dries the ink and adheres it to the material.

With UV printing, you can print custom designs, images, text, and textures onto many materials. This expands creativity and applications.

What is Pad printing?

Pad printing (also known as gravure printing) is an indirect offset printing technique that transfers the image from a base to an article via a silicone pad. Pad printing is widely used in the medical, automotive, promotional, apparel, electronics, as well as appliances, sporting equipment, and toy industries.

Comparison of UV printing and Pad printing

Next, I will compare the difference between the two processes from 5 aspects, so that you can see the difference between the two more clearly so that you can make a better choice.

1. Printing quality

UV printing has higher image quality and detail performance, suitable for complex and full-color printing.

· Pad printing technology can achieve good accuracy, but the number of colors is limited and only suitable for simple patterns.

2. Versatility and application

UV printing is suitable for almost all materials and shapes, including flat and three-dimensional items such as glass, metal, and plastic.

Pad printing has certain applications in specific areas, such as medical devices and toys, but is not suitable for complex shapes or full-color printing needs.

3. Cost-effectiveness

UV printing is cost-effective in both small and high-volume production as it does not require expensive preparation steps and additional color equipment.

Pad printing has a higher cost than multi-color printing and is suitable for long-term mass production.

4. Production speed

UV printing greatly reduces the production cycle due to its instant curing and fast preparation time, which is suitable for rapid delivery needs.

· Pad printing preparation time is long, suitable for a stable long-term production plan.

5. Environmental impact

· The ink used in UV printing is free of volatile organic compounds, reducing the negative impact on the environment.

· Solvents and cleaners used in pad printing can be a burden on the environment.

These comparisons show that UV printing technology is superior to traditional pad printing technology in many ways, especially in terms of adaptability, efficiency, and environmental protection.

When to Choose UV Printing?

You can choose UV printing at almost any time because it can print anything. It is a great choice for printing promotional items, not only for your business but also for your customers. If your customers have ordered custom items, then a UV printer is a great way to be a one-stop shop for all your needs, whether it is custom advertising signs car wraps, or golf balls for events (corporate charity events, basketballs, logos, magnets, stainless steel, glass, etc.).

When to Choose Pad Printing?

The best time to choose pad printing is when you need to produce in small batches, handle irregular shapes and complex surfaces, and require high durability and long-lasting printing. In addition, pad printing excels in handling multi-color small patterns and functional materials such as conductive inks and adhesives, making it very useful in medical devices, electronics, and industrial parts marking. If your project meets these requirements, pad printing will be a more economical and reliable choice.

Conclusion

When choosing between UV printing and pad printing, it is important to evaluate the advantages and disadvantages based on specific needs and application scenarios.

UV printing can provide higher image quality and more flexible applications in various materials and shapes, suitable for projects that require high accuracy and a variety of materials.

Pad printing, on the other hand, is more cost-effective when dealing with complex three-dimensional objects and high-volume production, and is widely used in fields such as medical equipment, electronic products, and industrial parts marking. The two technologies have their advantages and are suitable for different application scenarios and business requirements.

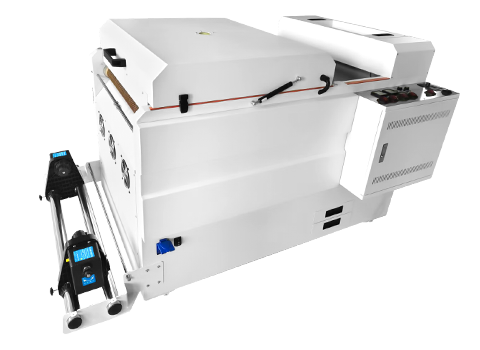

No matter which printing method you choose, it is important to ensure that you choose high-quality equipment. AGP offers high-quality UV printers with outstanding performance and reliability to meet your printing needs. Visit our website to learn more about AGP products to help you be more successful in your business.