Why can’t the powder on the DTF film be shaken off completely?

Hello! Fall is coming, and all kinds of printed jackets, printed sweatshirts, and printed T-shirts are ready to be worn. Are your DTF printers so busy that they are about to take off? As a professional manufacturer, AGP today will answer the main reasons why can’t the powder on the DTF film be shaken off completely. Let’s learn together~

In the field of digital printing, the status of DTF printers is impregnable. As a good partner of the DTF printer, the powder shaker is naturally more and more important. After all, it determines the firmness of the subsequent heat transfer pattern.

The working principle of the powder shaker is not complicated. Its main working process is to sprinkle powder, shake powder, and dry it. First, sprinkle hot melt powder evenly on the heat transfer pattern, then shake off the excess hot melt powder, and finally dry the heat transfer pattern sprinkled with hot melt powder. After learning the basic operation steps of a powder shaker, let's analyze the reasons why can’t the powder on the DTF film be shaken off completely.

1. Ink problems

If the white ink is too thin and has high moisture, it will easily cause ink bleeding (the oil and water of the white ink seeps beyond the edge of the pattern), which will cause too much hot melt powder to stick to the edge of the pattern when shaking powder. You can observe: that if there are water stains around the printed pattern before sprinkling powder, it can be determined to be an ink problem.

Solution: Changing the ink, or pre-drying before sprinkling can improve this condition.

2. Quality issues of DTF film

Under the same other consumables and the same production environment, if the powder sticking problem improves after changing to another type of DTF film. Then there is a high probability that the quality of the DTF film is poor or unqualified, or the compatibility between the DTF film and the ink is not good enough.

Solution: This problem can be solved by replacing the appropriate dtf film.

3. Hot melt powder problems

If the hot melt powder gets wet, it will stick together and form a lump., and obvious glue edges will appear on the edges of the pattern.

Solution: The hot melt powder needs to be moisture-proofed, or bake the dampened powder for a while, sift it, and then add it to the powder shaker.

4. Humidity problems

Excessive air humidity due to weather conditions will cause the white ink to dry slowly. If the white ink is too wet, too much hot melt powder will stick to the edges of the pattern, forming powder edges and glue edges. Solution: Choose a DTF printer and powder shaker with a front drying system.

It should be noted that when the air humidity is too high (higher than 65%), dehumidification needs to be performed to protect the machine.

5. Static electricity problems

If the machine is not grounded, the static electricity on the DTF film will be greater when the weather is dry, and the problem of powder sticking may easily occur.

Solution: Connecting the grounding wire to the machine can improve the problem.

6. Machine problems

If the above factors are eliminated and there is still unclean hot melt powder on the DTF film, it may be that the quality of the powder shaker is not up to standard.

Generally speaking, a high-quality DTF Powder Shaker operates in five stages: pre-drying - circulating vibrating powder dusting - separation and beating powder - suction tunnel drying - material collection

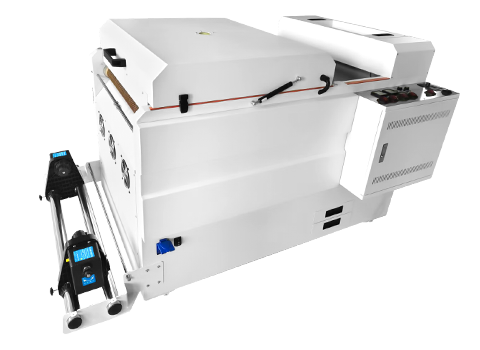

AGP H650 PRO dtf powder shaker is equipped with a pre-baking plate at the front of the powder dusting device, which can effectively reduce powder residue outside the dtf film pattern;

The spiral dragon blade is used to circulate the powder so that the hot melt powder can be spread more evenly on the heat transfer pattern, so that the subsequent hot melt glue will be more evenly distributed, increasing the adhesion to the fabric, and the pattern will naturally be stronger. Moreover, sprinkling powder in this way can also reduce the probability of powder agglomeration and make it less likely to block the filter;

The powder shaking process adopts the separate patting method, and the strength of the shaking can be adjusted as needed. Paired with a 750mm extended drying tunnel - two-stage independent heating, drying is more even, effectively avoiding problems such as oil and moisture return, and there will be no offset printing problems around the pattern during pressing;

Adopting the guide belt feeding method and equipped with vacuum suction, the feeding operation is simple and will not cause waste of film;

Equipped with dual-power paper take-up system, automatic induction rewinding, independent and can be cut at any time, making proofing more convenient;

Equipped with two languages control screen to realize touch screen integrated control, making every function easier to use;

The H650 PRO high-speed powder shaker combined with the DTF-T652/653/654 printer allows you to easily achieve high-resolution printing, and dusting powder to fix color, drying, and winding! For more details about the machine, please feel free to chat privately!

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Welcome to AGP! With nearly a decade of experience in the printer industry, we specialize in R&D and manufacturing, offering exclusive DTF and UV DTF printer solutions. With a global presence, including partnerships in the USA, Canada, UK, Italy, and Spain, we’re ready to take the next step in business expansion together!

Contact Us:

Email: info@agoodprinter.com

WhatsApp: +86 17740405829