Why does DTF printing have white edges?

DTF (direct-to-film) printing has gained industry acclaim for its impressive pattern transfer effects, rivaling even the clarity and realism of photos. However, as with any precision instrument, minor issues may surface. One common concern is the occurrence of white edges in the final printed products, impacting overall appearance. Let's explore the causes and effective solutions together.

1. Printhead Precision

A properly adjusted and well-maintained printhead is crucial for flawless DTF printing.

Irregularities such as impurities or prolonged periods without cleaning can lead to problems like flying ink, ink blocking, and the appearance of white edges.

Daily maintenance, including regular cleaning, ensures optimal printhead performance.

Adjust the printhead height to a precise range (approximately 1.5-2mm) to avoid damage or inaccurate ink placement.

2. Static Electricity Challenges

Winter weather intensifies dryness, increasing the likelihood of static electricity.

DTF printers, relying on a computer-controlled image output, are susceptible to static electricity due to their short internal electric circuit spacing.

High static electricity levels can cause film movement issues, wrinkles, ink dispersion, and white edges.

Mitigate static electricity by controlling indoor temperature and humidity (50%-75%, 15℃-30℃), grounding the DTF printer with a cable, and manually removing static before each print using alcohol.

3. Pattern-Related Concerns

Occasionally, white edges may not stem from equipment malfunctions but rather from the provided patterns.

If customers supply patterns with concealed white edges, modify them using PS drawing software to eliminate the issue.

4. Consumables Problem

Please change to better PET film which uses anti-static and oil-based coating. Here AGP can offer you high-quality PET film for testing.

Anti-static hot melt powder is also very important.

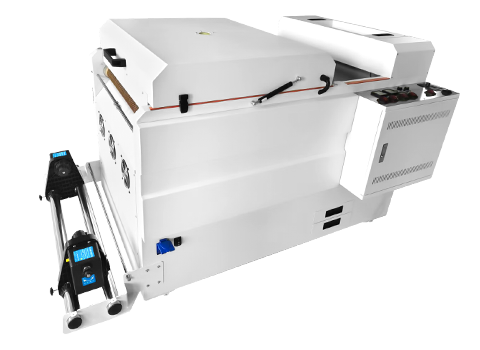

In the event of white edges during the printing process, follow the provided methods for self-examination and resolution. For further assistance, contact our technicians. Stay tuned for additional insights into optimizing AGP DTF printer performance.