Why DTF Printing is Revolutionizing the Textile Industry

Why DTF Printing Will Revolutionize the Textile Industry

Introduction:

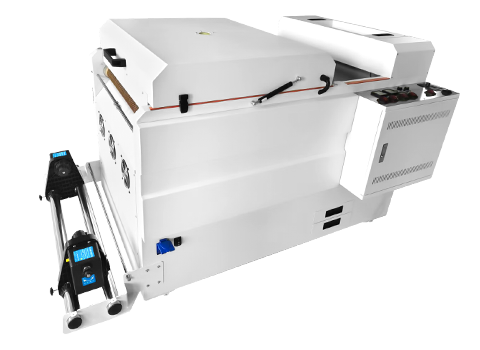

The textile industry has made numerous technological advances over the years, and digital printing technology has played a key role in revolutionizing the way fabrics are manufactured. One such innovation that has received a great deal of attention is Direct-to-Film (DTF) printing. DTF printing is revolutionizing the textile industry by offering a variety of previously unimaginable benefits and possibilities. In this article, we will explore the reasons for the growing popularity of DTF printing and how it is changing the textile industry.

Improved Print Quality:

DTF printing utilizes advanced printing techniques that enable high-resolution, vibrant printing on a wide variety of fabrics. Unlike traditional printing methods, DTF printing allows for intricate detail, sharp lines, and a wide color gamut, resulting in superior print quality. This level of precision and detail brings designs to life and enhances the overall aesthetic of the textile product.

Versatility and Flexibility:

One of the key advantages of DTF printing is its versatility. It supports printing on a wide range of fabrics, including cotton, polyester, blends, and even synthetic materials. This flexibility opens up opportunities for textile manufacturers, fashion designers, and entrepreneurs to create unique and customized products. DTF printing enables the production of personalized garments, accessories, and home textiles to meet the market's growing demand for individuality and customization.

Cost-effectiveness:

DTF printing is an attractive option for textile manufacturers due to its cost advantages over traditional printing methods. The process eliminates the need for expensive screens, plates, and stencils, significantly reducing set-up costs. In addition, DTF printing enables on-demand production, eliminating the need for large inventories and reducing the risk of overstocking. This cost-effective approach allows companies to quickly adapt to changing market.

Durability and Washability:

Textile products are subjected to repeated washing and wear and require durable prints that can withstand these conditions. DTF printing offers superior durability and washability, ensuring that prints remain vibrant and unimpaired even after multiple washes. This durability is achieved by the fusion of the ink and fabric fibers, resulting in prints that resist fading, cracking, and peeling. Print quality is maintained over time, thus increasing the value and longevity of the textile product.

Conclusion:

DTF printing is revolutionizing the textile industry by providing print quality, versatility, cost-effectiveness, quick turnaround, environmental sustainability, and durability. As companies strive to meet the evolving demands of consumers, DTF Printing offers innovative solutions that enable customization, reduce costs, and increase productivity. By adopting this cutting-edge technology, textile manufacturers and designers can explore new opportunities and gain an edge in a dynamic and competitive industry. The future of the textile industry depends on innovative technologies like DTF printing, where creativity and efficiency combine to shape the fabrics of tomorrow.